FanCheng Влияние естественной движущей силы промышленных роботов: изменение численности населения

Опубликован в:2020-06-30

The change of population structure and the surge of labor costs are often the natural driving forces for the growth of the number of industrial robots in various countries. When the economy grows rapidly, there will be higher requirements for the number of labor force. When the proportion of labor force decreases, the change of population structure makes the number of labor force unable to meet the growing demand for labor. Industrial robots, as a substitute for labor force, should be born. As a result of the contradiction between labor supply and demand, the surge in labor costs continues to promote the automation transformation of industrial enterprises and drive the continuous growth of the number of industrial robots. Japan, South Korea, Germany and other countries with relatively developed industrial robot industry in the world, the incentive for the initial development of their industrial robot industry is the change of population structure.

1. Japan: aging population makes robots on the stage of industrial production

In 1967, Kawasaki heavy industry company introduced robots and related technologies from the United States Union, the worlds first robot enterprise, and established a production workshop. The next year, it successfully developed the first Kawasaki robot. With the improvement of Japans annual economic growth rate, Japans labor force is far from meeting the needs of rapid economic development. The emergence of industrial robots has effectively solved this problem.

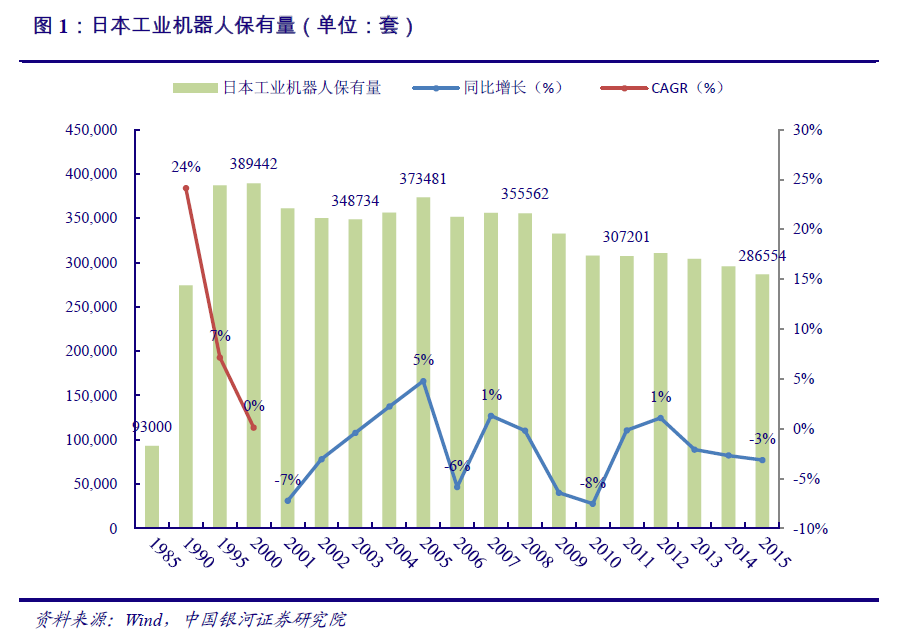

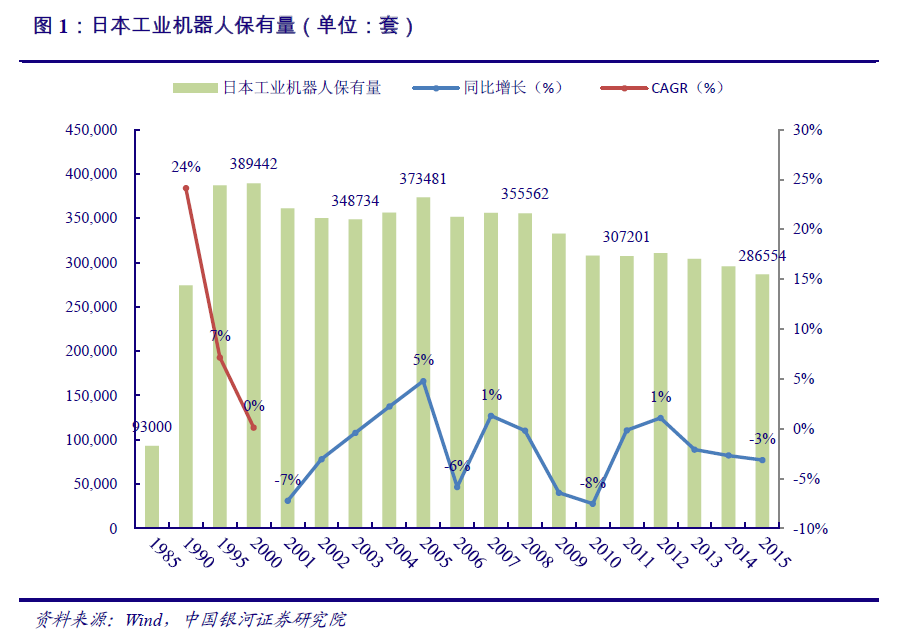

From the late 1950s to 1960s, the baby boom in Japan gradually faded, the growth of Japanese labor force slowed down around 1975, and industrial robots began to sprout and develop. From 1985 to 2000, the number of industrial robots in Japan grew rapidly, from 90000 to 390000, showing a trend of rapid development in the early stage; During the period from 2000 to 2008, the number of units remained basically stable, at the level of about 350000 units; After 2008, Japans manufacturing industry gradually shifted abroad, and the downstream demand decreased, resulting in the gradual decline of the number of industrial robots in Japan.

After World War II, Japans economy grew rapidly and its production demand was strong. After the end of World War II, Japan took steel and coal as a breakthrough to restore its economy, and the United States as a model in production and consumption. Therefore, the technology needed for this purpose can be industrialized and commercialized quickly without developing from scratch and introducing advanced technology. Therefore, Japan ushered in rapid economic growth through imitation, digestion and improvement.

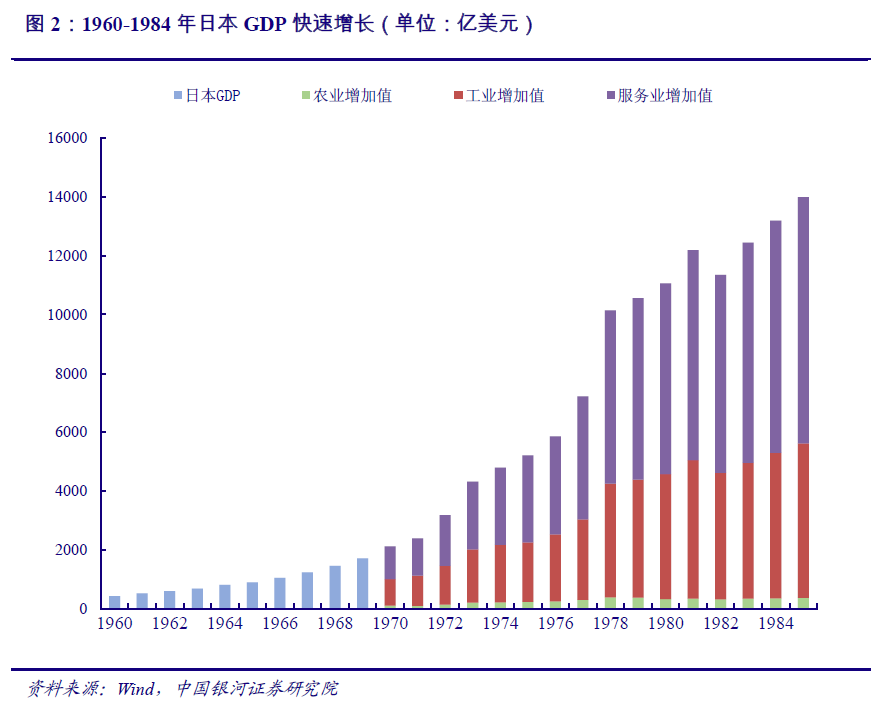

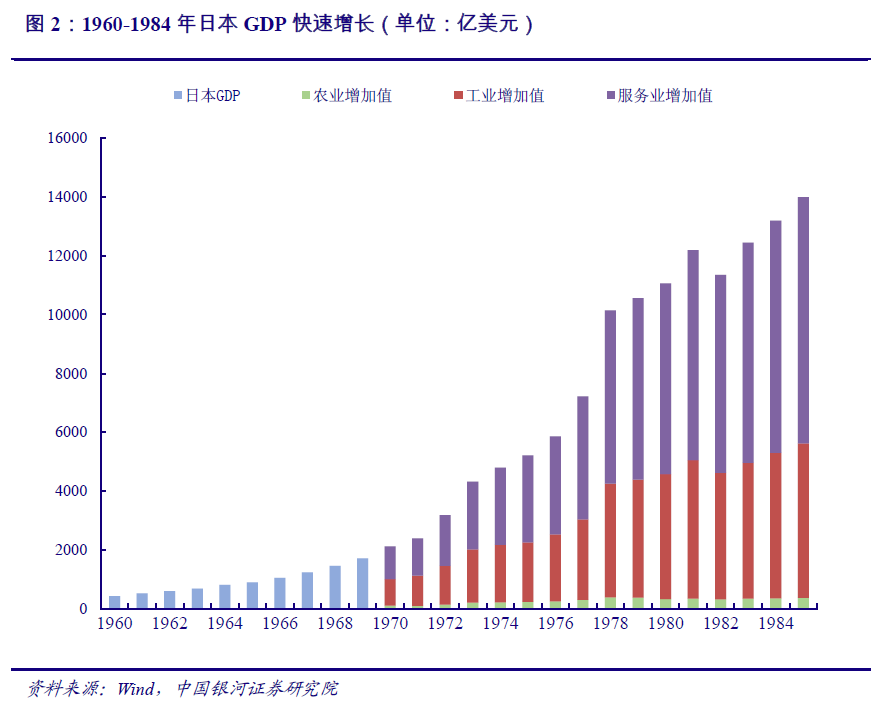

In 1960, Japans GDP was only US $44.3 billion, which rose to US $1105.4 billion in 1980, with a CAGR of 17.45%. During this period, the proportion of industrial added value in GDP remained at 37% - 43%, which contributed greatly to economic growth. Under the background of rapid economic growth, the demand for industrial production was so strong that the demand for labor continued to expand.

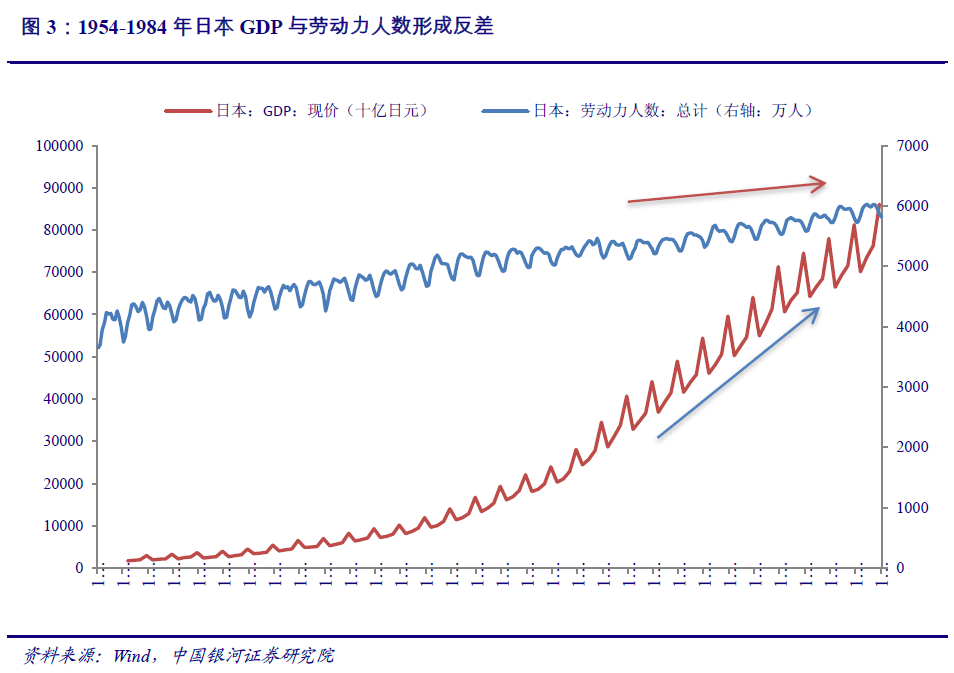

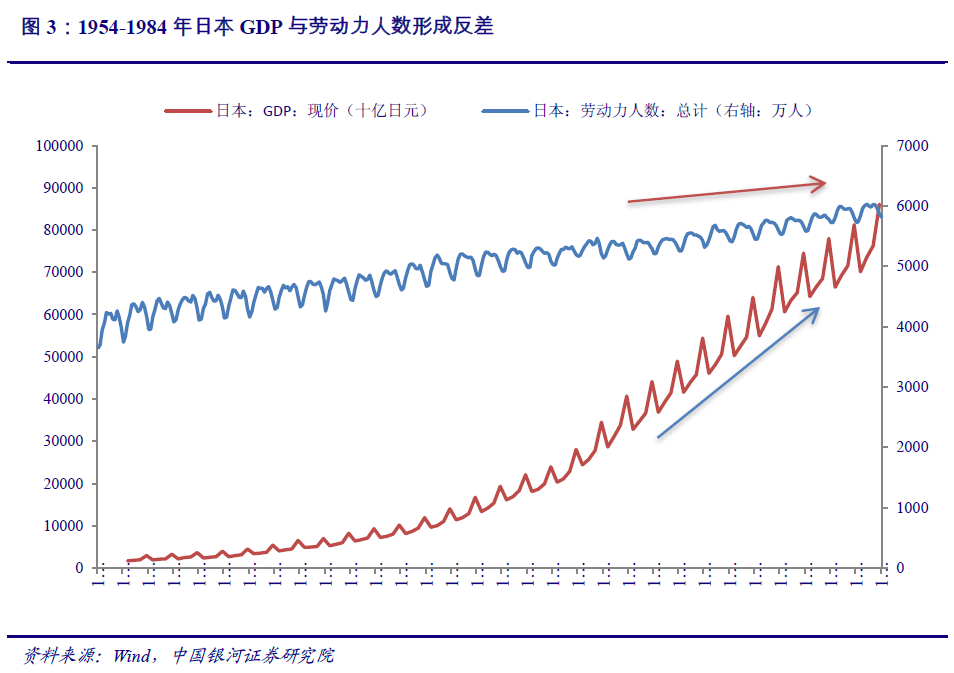

The proportion of the working population has declined, in contrast to the rapidly growing GDP. After 1945, more than 5 million young and middle-aged veterans and migrant returnees set off a baby boom in Japan. From 1945 to 1949, the birth rate reached more than 33%, which decreased slightly from 1950 to 1954, but remained at a high level of more than 20%. Overall, the average birth rate in Japan during the decade 1945-1954 was about 28%, and the average population aged 13 and under was about 27 million, accounting for 32% of the total population. This batch of baby boomers made Japans labor force population rise rapidly in the 1960s-1970s. From the late 1950s to the 1960s, the baby boom gradually faded. Therefore, from around 1975, the growth of Japans labor force began to slow down, and the proportion of labor force in the total population decreased compared with before. The decline in the proportion of labor force was in sharp contrast to the high growth rate of GDP at that time. The shortage of labor force was difficult to support Japans development policy inclined to heavy industry for a long time.

In 1969, the total population of Japan was 103.172 million, the population aged 15-64 was 71.224 million, and the proportion of labor force population reached 69.03%, ranking first in the world; In 1977, the total population was 113.863 million, and the population aged 15-64 was 7, 6.829 million, and the proportion of labor force dropped to 67.47%, ranking fifth in the world. In 1970, the proportion of the population over 65 years old in Japan has exceeded 7%. According to the new standards of the United Nations, the region is regarded as entering an aging society when the elderly aged 65 account for 7% of the total population. Therefore, Japan officially entered an aging society in 1970.

Before 1990, the proportion of Japans population aged 65 and over in the total population increased slowly, from 5.62% in 1960 to 11.87% in 1990. The slope of the fitting straight line in this time interval was 0.20. Since 1990, the proportion of the population aged 15-64 in Japan has continued to decline. At the same time, the proportion of the population aged 65 and over has increased rapidly, and the slope of the fitting straight line has changed to 0.57, which has significantly accelerated the aging rate in Japan.

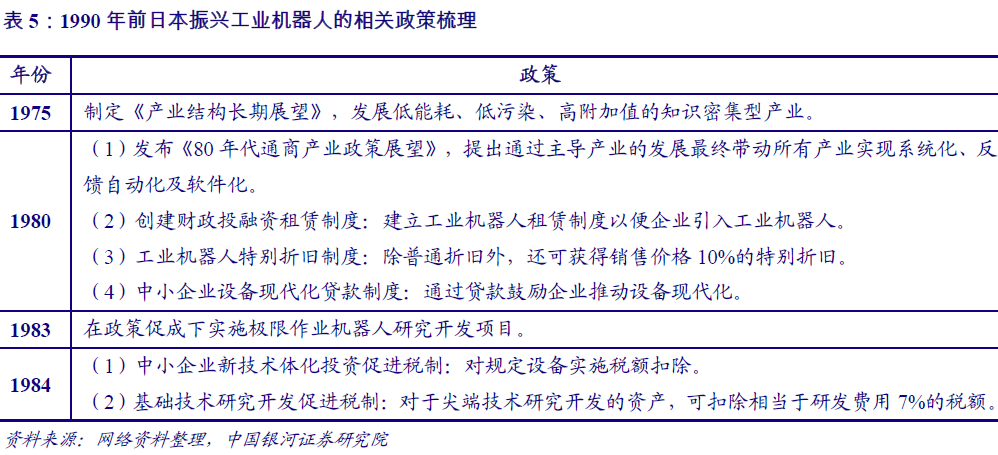

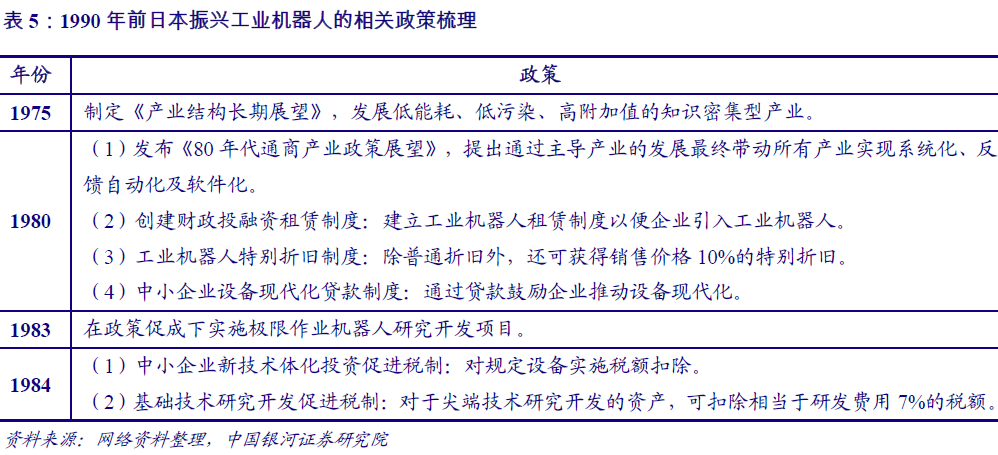

The shortage of labor force, coupled with policy support, boosted the early growth of industrial robots. In the context of rapid economic growth, the demand for labor force dominated by young labor force is expanding, resulting in the trend of insufficient labor supply. The change of population structure makes the employment situation of enterprises worse. At this time, it happened that the first industrial robot "unimate" had just been born. Although the technology was not mature, it was unable to meet the production demand due to labor shortage. In addition, the Japanese government issued a number of policies to promote the popularization of industrial robots. Japanese enterprises began to use industrial robots one after another, and the number of industrial robots gradually increased rapidly.

Since the 1980s, Japans industrial robot ownership and shipment index have risen rapidly. In 1980, it was called the first year of the popularity of industrial robots in Japan. The output value increased by 85% compared with 1979, reaching 78.4 billion yen (equivalent to about 800 million yuan), and the output reached 19900 units, forming an emerging industry. In 1983, Japans industrial robot producer shipment index was 10.20 (2010 = 100), which rose to 66.50 in 1990, and CAGR was 30.71%.

At the same time, Japan had 93000 sets of industrial robots in 1985, accounting for about 70% of the worlds industrial robots. In 1990, it had 274210 sets, an increase of 194.85% in 10 years. It was the most developed country in the worlds industrial robot industry at that time.

The change of population structure leads to the shortage of labor force, which leads to the increase of labor cost in manufacturing industry, and continues to drive the steady growth of the number of industrial robots. The conflict between a large number of labor demand and the shortage of labor leads to the rapid rise of labor costs, forcing enterprises to increase the proportion of industrial robots as a solution to reduce production costs. As two countries with relatively developed industrial robot industry in the world, Japan and Germany benefit from the rise of labor cost in the second stage of industrial robot development.

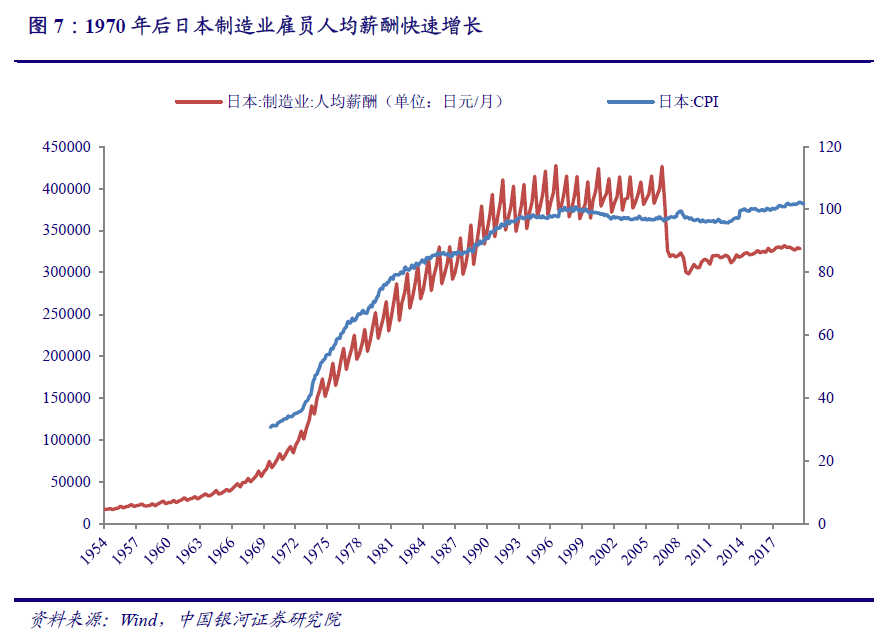

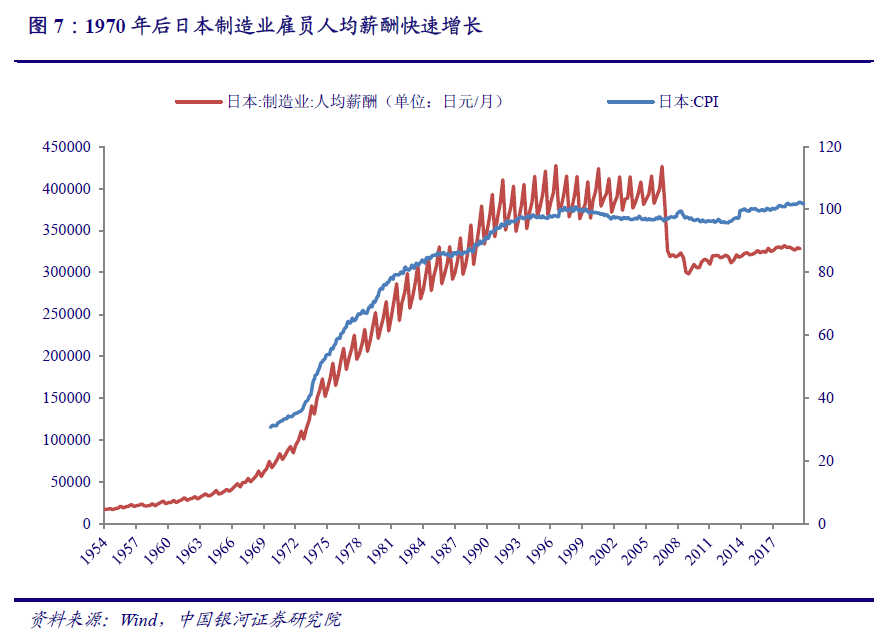

The growth of labor force peaked, and the shortage of labor supply led to the continuous rise of per capita salary in the manufacturing industry. From 1980s to 1990s, Japans industrial sectors represented by coal, steel and electric power continued to develop, so there has always been a great demand for manufacturing employees. On the other hand, with the gradual progress of the technology and application of industrial robots, the number of industrial robots in Japan remained high until 2005.

On the one hand, the labor supply is weak, on the other hand, the labor demand far exceeds the total number of existing labor force in Japan. Therefore, the per capita salary growth of manufacturing employees is significantly faster than that of the number of employees. At the same time, because of the rapid development of Japanese economy and the market bubble, the salary level and the price level of the employees rose synchronously and rapidly. However, in the same period, the wage gap between manufacturing and non manufacturing industries widened significantly after 1990. We believe that the conflict between supply and demand of labor in manufacturing industry is the main reason for the surge of labor costs.

The per capita salary of manufacturing industry continued to rise, which was significantly higher than that of non manufacturing industry. In 1990, the per capita salary of manufacturing industry was 360459 yen / month and that of non manufacturing industry was 321402 yen / month. The difference between the two was only 39057 yen / month (the exchange rate in 1990 was about 100 yen to 4 yuan). The per capita salary of manufacturing industry was 12.15% higher than that of non manufacturing industry. Subsequently, the gap continued to expand. In 1995, the per capita salary gap between manufacturing and non manufacturing industries was as high as 42674 yen / month, and the per capita salary of manufacturing industry was 12.30% higher than that of non manufacturing industry; In 2000, the per capita salary of manufacturing industry was 393174 yen / month and that of non manufacturing industry was 327039 yen / month, with a gap of 66%, 135 yen / month, the per capita salary of manufacturing industry is 20.22% higher than that of non manufacturing industry.

After 2007, the more mature industrial robot technology and the higher cost performance brought by the use of robots have solved the labor demand of enterprises. During this period, due to the impact of the financial crisis, the per capita salary of manufacturing employees gradually decreased to about 320000 yen / month, and the gap between the per capita salary of manufacturing employees and non manufacturing employees gradually decreased and remained at 50000 yen / month. From the reasons of salary changes before 2006, the rapid growth of salary before 1990 was caused by the decline of the proportion of employed population, which led to the salary growth of manufacturing industry and non manufacturing industry almost at the same pace. After 1990, the salary shock of manufacturing industry rose, while the salary growth of non manufacturing industry slowed down and gradually decreased, and the salary gap between manufacturing industry and non manufacturing industry gradually widened, The salary difference will gradually transfer the labor force to the manufacturing industry with high salary. At the same time, it will also promote the development of labor substitution products with high cost performance such as industrial robots.

The increase of labor cost makes the demand of industrial production more and more urgent, and promotes the great leap forward development of industrial robots. On the one hand, due to the squeeze of higher labor costs on the companys profit space, Japanese enterprises have chosen to continue to expand the use of industrial robots to reduce costs. On the other hand, from 1970 to 2000, industrial robots changed from hydraulic power assisted control to electric power assisted control, and gradually added visual recognition and mechanical control. Various research results have made continuous progress and have been mature and applied to industrial robot products. Therefore, the density of industrial robots in Japan has achieved leapfrog development at this stage. In 1985, the density of industrial robots in Japan was 103 units / 10000 workers, which continued to grow in the next 15 years. In 1990, 1995 and 2000, it was 282, 362 and 385 units / 10000 workers respectively.

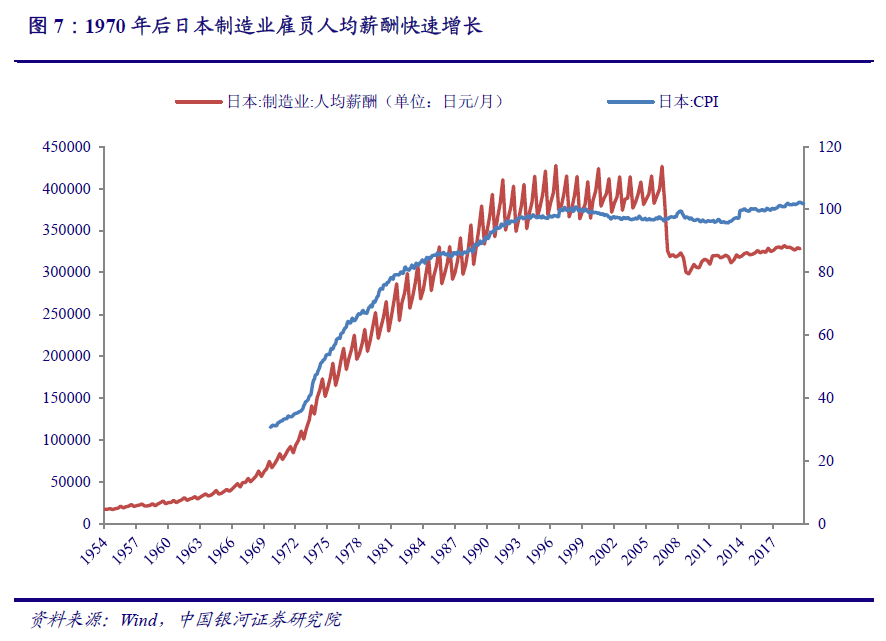

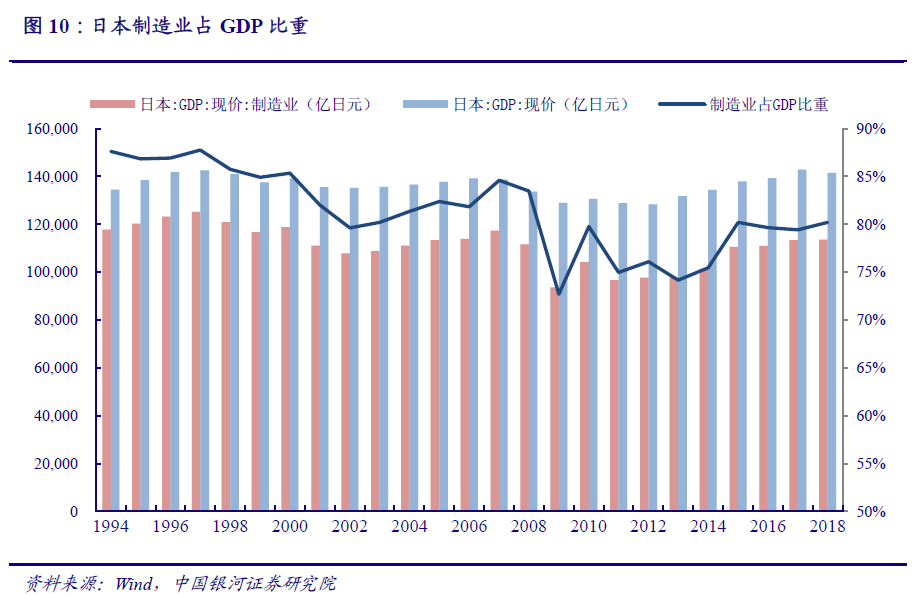

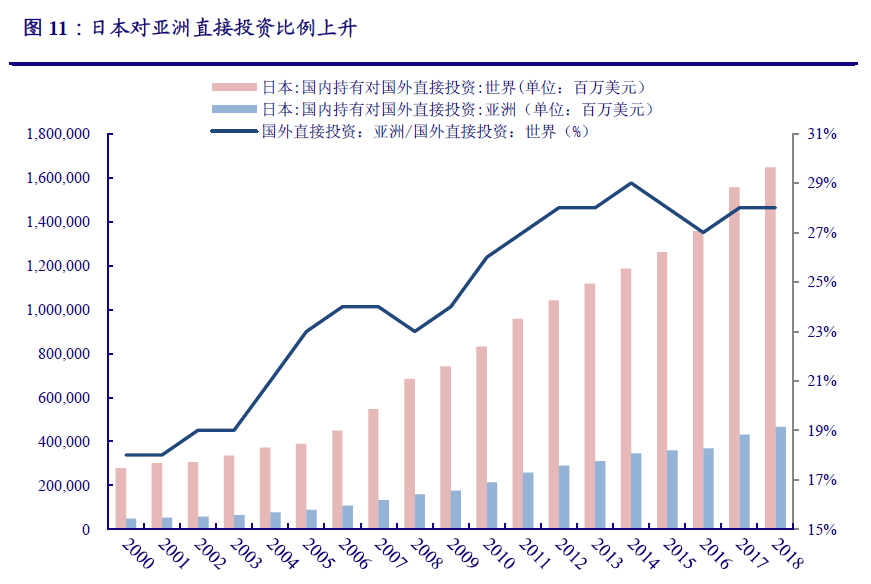

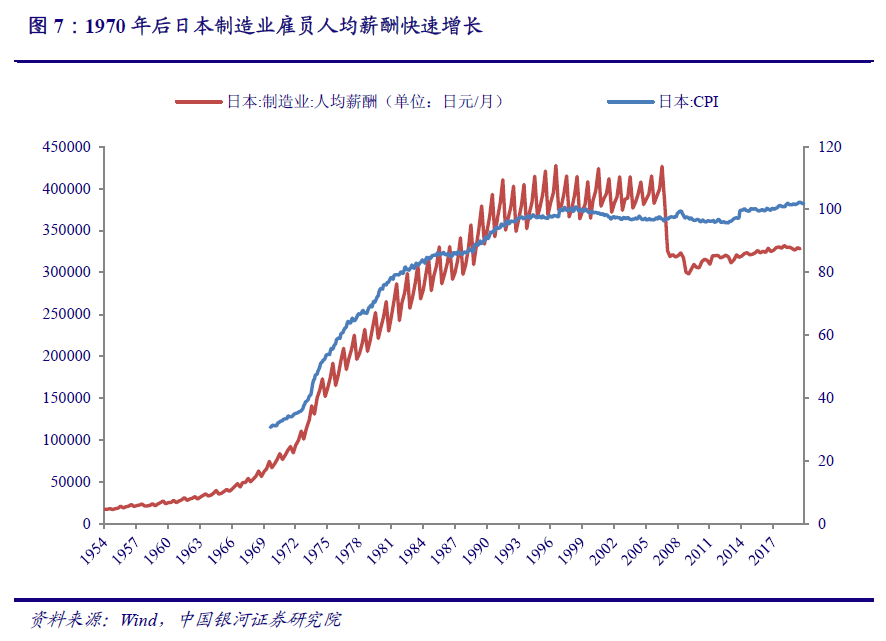

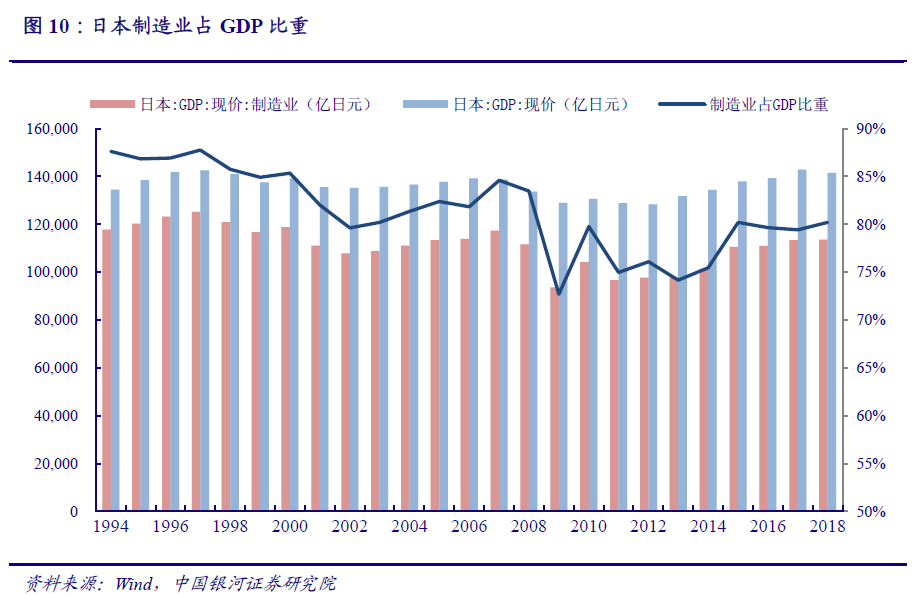

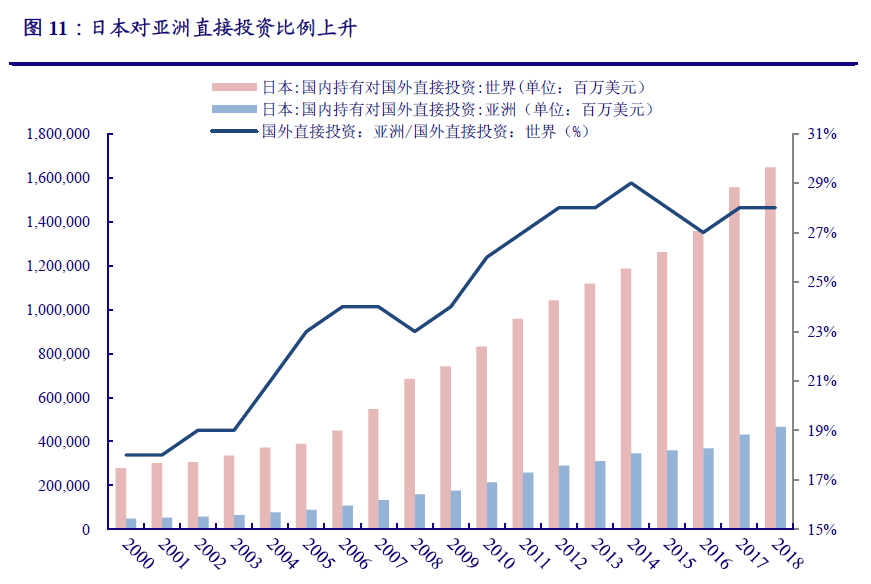

The transfer of labor-intensive industries, the number of industrial robots in Japan stagnated. Different from most countries, due to its geographical environment and comprehensive consideration of economy, Japan gradually transferred its domestic labor-intensive industries to China and other Southeast Asian countries with low labor cost at the end of the 20th century and the beginning of the 21st century. During this period, the proportion of Japans domestic manufacturing industry in GDP also decreased, In addition, the financial crisis in 2008 led to a sharp plunge in the per capita salary of the manufacturing industry. The growth of the number of industrial robots brought by labor shortage in Japan basically peaked. The density of industrial robots in Japan reached its peak in 2005 (409 sets / 10000 workers). In recent ten years, the supply and demand of labor have been in a relatively balanced state, and the density of industrial robots has stabilized at about 330 sets / 10000 workers.

2. Germany: conflict between industrial manufacturing power and high labor cost

Similar to Japan, the changes in population structure and labor costs are relatively high, driving the vigorous development of German industrial robots. The reason why German manufacturing dominates the world is that Germany has a very high level of robot automation application. As early as the 1980s, Germany began the process of "machine replacement". The number of industrial robots in Germany has been steadily increasing year by year.

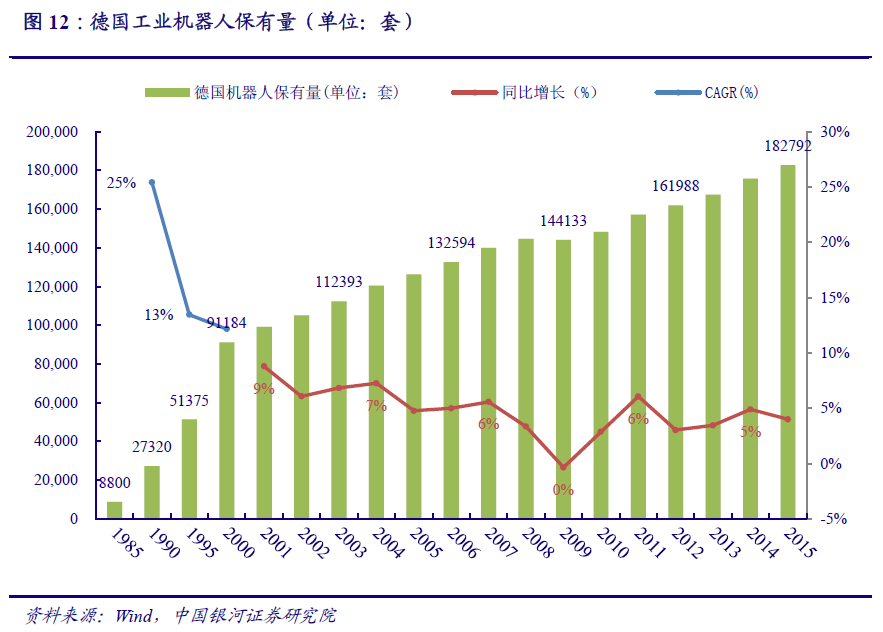

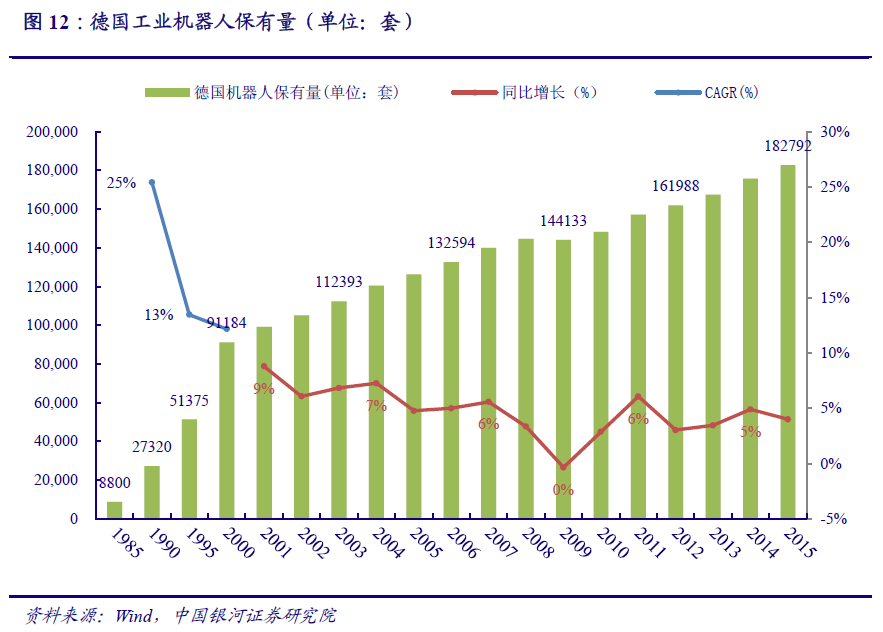

German industrial robots started to develop in the 1980s. From 1985 to 2000, the number of industrial robots in Germany increased rapidly, from 8800 to 91184, and the CAGR reached 16.87%; After 2000, the change of population structure accelerated, superimposed with the increase of labor cost, and the number of industrial robots in Germany continued to grow steadily. In 2015, the number of industrial robots increased to 183000, and the CAGR was 4.75%.

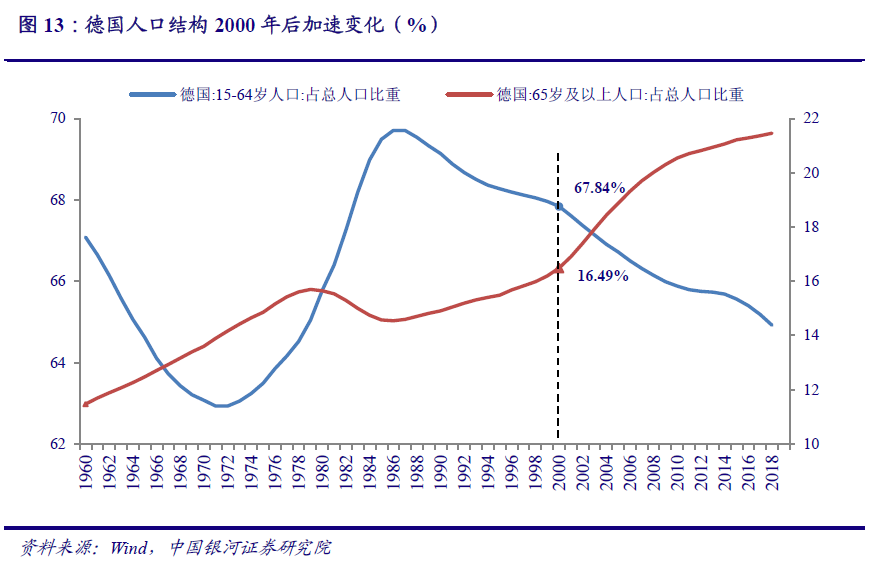

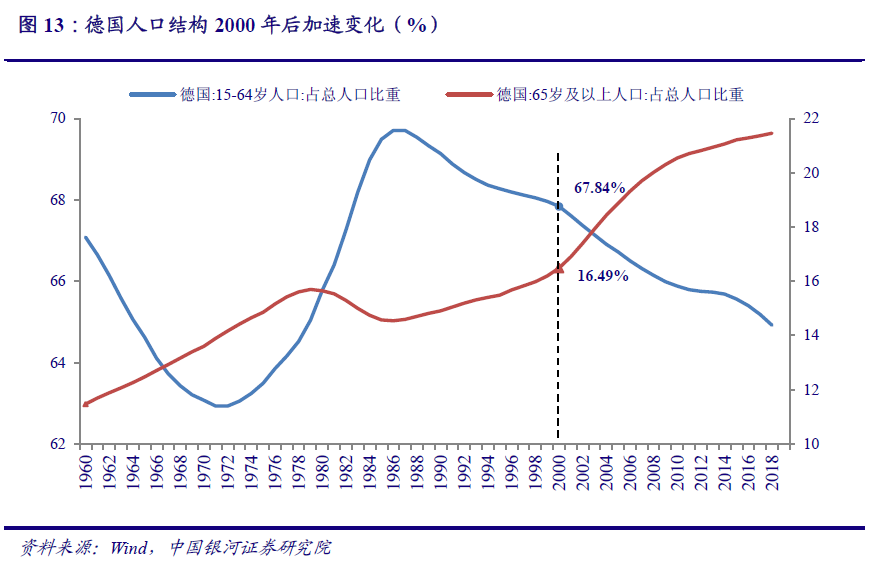

Around 2000, the change of German population structure accelerated, giving birth to the development of industrial robots. Since 2000, the aging rate in Germany has accelerated significantly. While the proportion of the population aged 65 and over has increased, the proportion of the labor force has declined rapidly. The change of population structure has given birth to the development of industrial robots as an incentive.

With the expansion of German manufacturing industry, the demand for labor has expanded accordingly. In the 1990s, the German government and enterprises attached great importance to promoting the adjustment of industrial structure through technological progress. In 1995, Germany issued the "manufacturing technology 2000 framework plan", taking "using information and communication technology to promote the modernization of manufacturing industry" as the main goal of the plan, and successfully realized industrial expansion. In 2000, the added value of German manufacturing industry was 433.3 billion euros, and in 2010, the added value of German manufacturing industry was 5, 05.1 billion euros, an increase of 17% over the past decade, and the demand for labor has increased accordingly; The labor force population in Germany was 40.44 million in 2000 and 42.47 million in 2010, an increase of only 5.0% over the past decade. The high growth rate of manufacturing added value is in strong contrast to the slow growth of the labor force population.

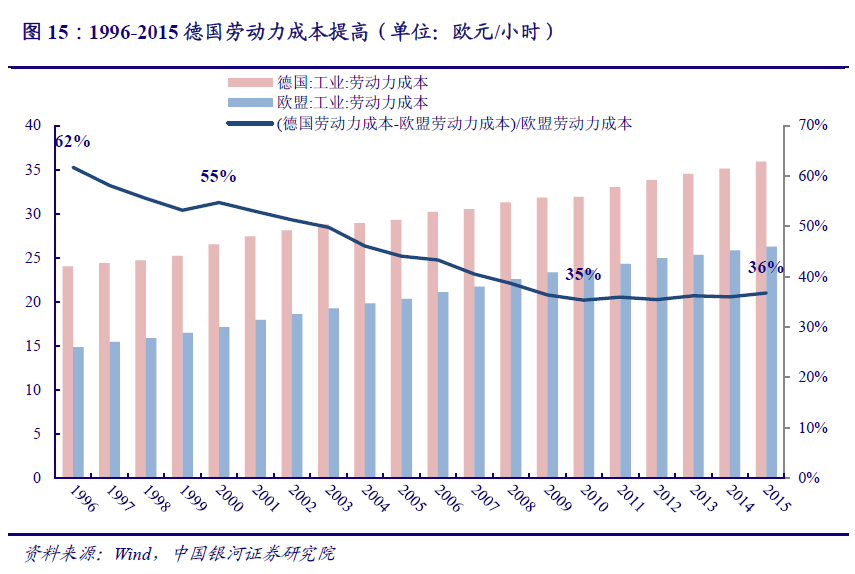

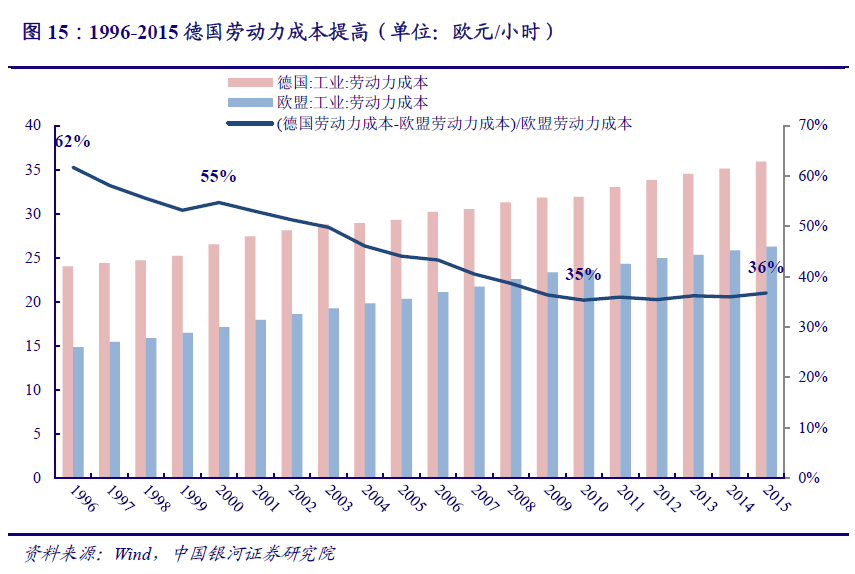

Germanys labor market is in short supply, driving up labor costs. Labor shortage follows the change of population structure and is directly reflected in the salary level of manufacturing employees. In 1996, the cost of industrial labor in Germany was 24 euros / hour and that in the EU was 14.8 euros / hour. The cost of industrial labor in Germany was 62% higher than that in the EU. The high labor cost forced German enterprises to replace labor with industrial robots.

With the gradual popularization of industrial robots, although the labor cost in Germany is still rising, the gap between Germany and the EU is gradually narrowing. In 2000, the labor cost in Germany was 55% higher than the EU average level, and the gap was reduced to 35% in 2010, and then gradually stabilized. In this ratio, the penetration of industrial robots has slowed down the rapid rise of labor cost to a certain extent.

The increase in labor costs in Germany has driven the increase in the number of industrial robots. Labor intensive industries such as automobile, machinery manufacturing, chemical industry, medicine, electronics and electrical appliances are the four traditional pillar industries in Germany. Germany firmly occupies the high-end position in the global industrial chain. In the 1990s, Germanys rising labor costs occupied the profit space of enterprises. On the one hand, in order to reduce production costs, on the other hand, in order to establish the golden signboard of "made in Germany", German enterprises continued to expand the application of industrial robots in the above industries. The number of industrial robots in Germany was 91184 in 2000, 148256 in 2010, and CAGR reached 5.0%; In 2010, the global number of industrial robots was 1059, 162 sets, with Germany accounting for 14%. The great changes in population structure, the increase in employee salary and the increase in labor cost are the driving forces for Germany to continuously promote the replacement of labor force by industrial robots and realize the great leap forward development of industrial robots. Now these factors still drive the development of industrial robots in Germany.

3. Korea: high aging & amp; Low Fertility Society promotes the development of robot industry

Reviewing the development history of industrial robots in Korea, we can find that around 1990 is the key time point for the development of its robot industry, and there is a contradiction between a large number of industrial production and labor demand. Similar to Japan, the emergence of industrial robots in South Korea in the 1990s also provided an opportunity for the conflict between rapid economic growth and population structure change.

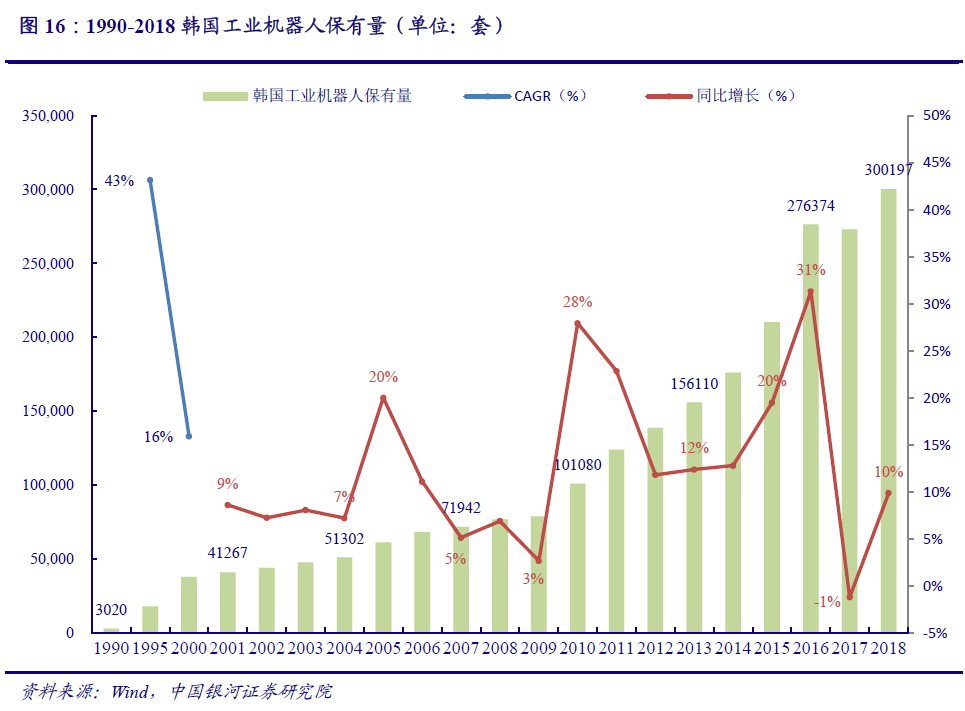

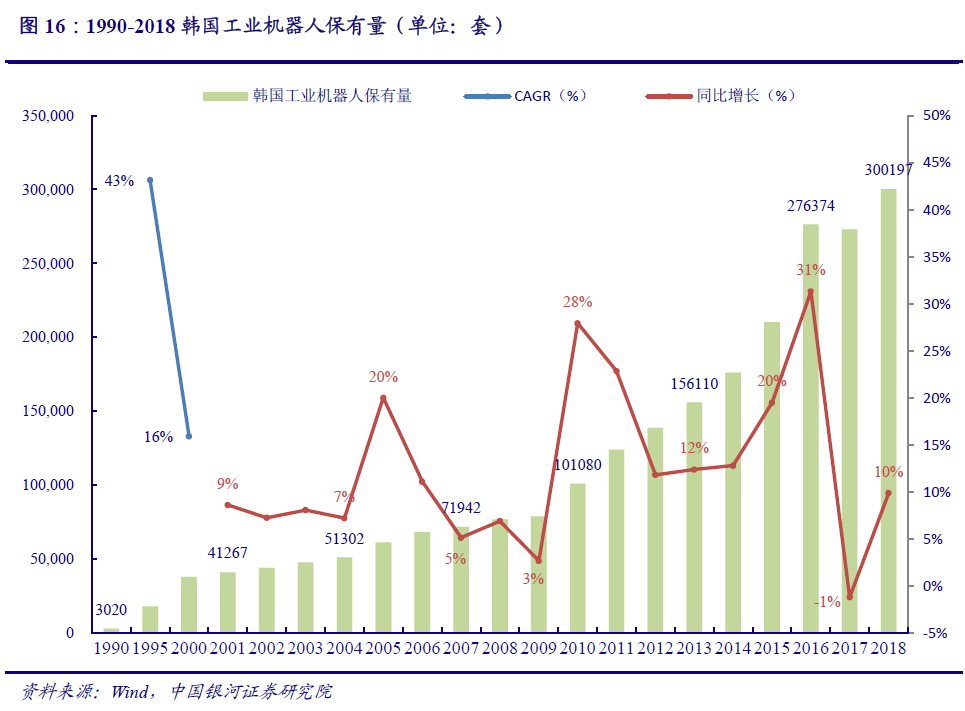

In 1990, industrial robots in South Korea began to develop, and then their ownership continued to grow rapidly. From 1990 to 2000, under the influence of the contradiction between rapid GDP growth and population aging, the number of industrial robots increased from 3020 to 37988, and the CAGR was as high as 28.81%. By 2018, the number of industrial robots in South Korea reached 300000. Benefit from Korean auto & amp; With the development of 3C industry, the demand for industrial robots is high. After 2010, the growth rate of industrial robots in South Korea remains at a high level.

Adjusting the export-oriented economic development strategy, South Koreas GDP increased rapidly. In the early 1960s, South Korea actively pursued the export-oriented economic development strategy, vigorously promoted the processing industry, increased exports and earned foreign exchange, quickly got rid of poverty and backwardness, and accelerated industrialization and modernization. After the 1990s, in order to transform its original government led export-oriented economy into a market-oriented export-oriented economy and optimize the industrial structure, South Korea carried out a new round of adjustment of its export-oriented economic development strategy, made use of the opportunity of industrial transfer from developed countries, combined with its national conditions, vigorously introduced advanced technology, and realized the transformation of industrial structure from capital intensive to technology Knowledge intensive upgrading has ushered in rapid economic growth.

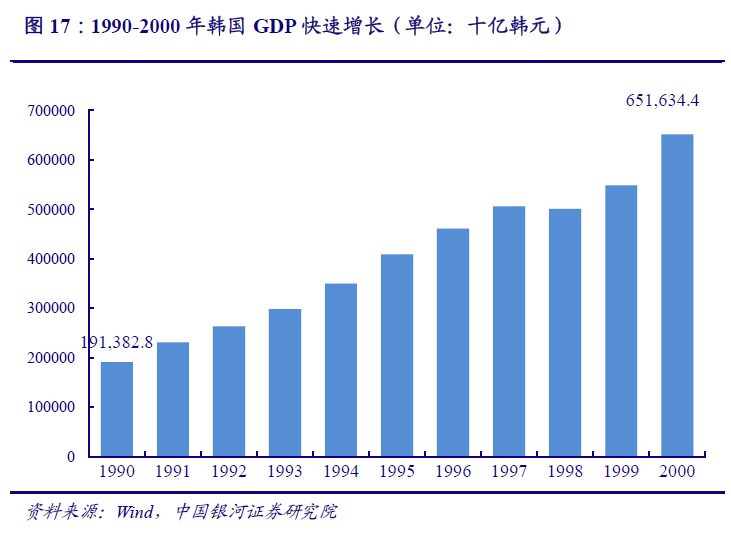

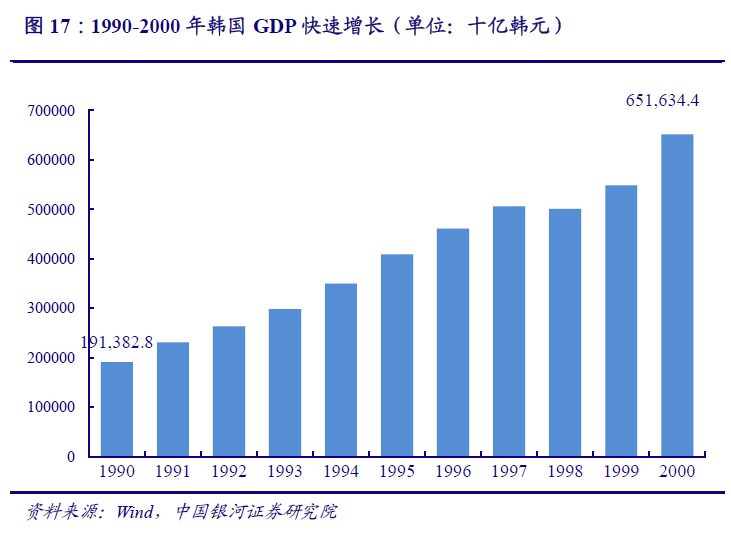

In 1990, the total GDP of South Korea was 191.38 trillion won, the per capita GDP was 6516 US dollars, and that of China was 317 US dollars. The per capita GDP of South Korea was about 21 times that of China. In 2000, the total GDP of South Korea increased to 651.63 trillion won, with a compound growth rate of 13%.

In the 1970s, South Korea implemented two five-year plans, aiming at shipbuilding, automobile production, steel, chemical industry and other heavy industries. The development of heavy industry has brought unprecedented speed to South Koreas economic development. Subsequently, South Korea mainly relied on exports to promote its economic growth. Manufactured products such as electronics, ships, automobiles and steel were its most important export products. In 1986, Hyundai made an important decision to enter the American automobile market. The vigorous development of automobile industry provides a good opportunity for the growth of industrial robots.

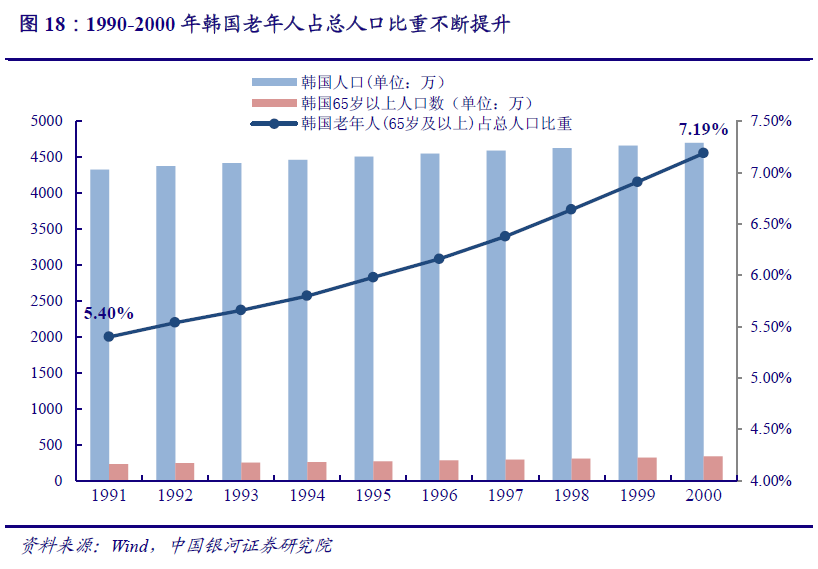

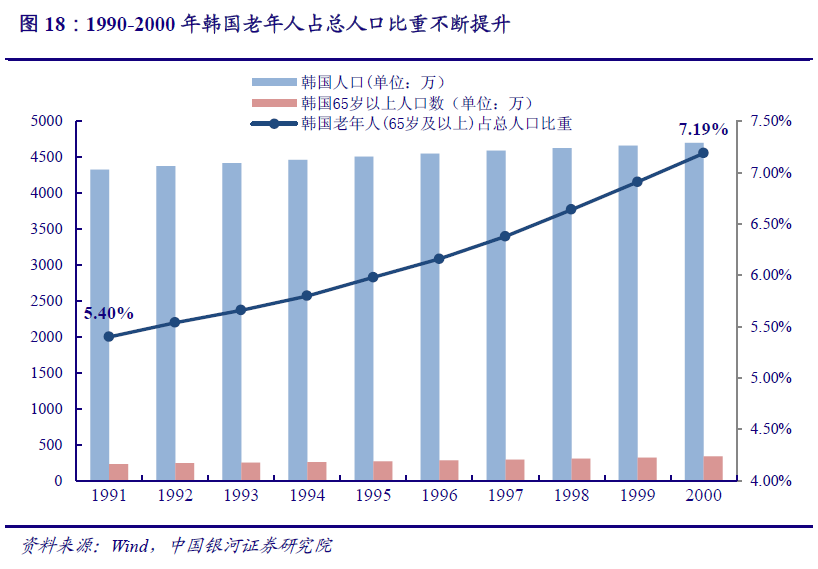

With the change of population structure in South Korea, the problem of aging is becoming more and more serious. In the 1990s, South Koreas fertility rate continued to decline and the total population grew slowly, while the increasing number of people over 65 led to the rapid increase of the proportion of the elderly in the total population. In 1990, the total population of South Korea was 42.87 million, the population over 65 years old was 2.24 million, and the elderly accounted for 5.23% of the total population. In 2000, the total population of South Korea was 47.01 million, the population over 65 years old was 3.38 million, and the elderly accounted for 7.19% of the total population, which means that South Korea has officially entered the "aging society". The aging problem is becoming more and more serious due to the change of population structure. Like Japan, South Korea also has the problem of labor shortage.

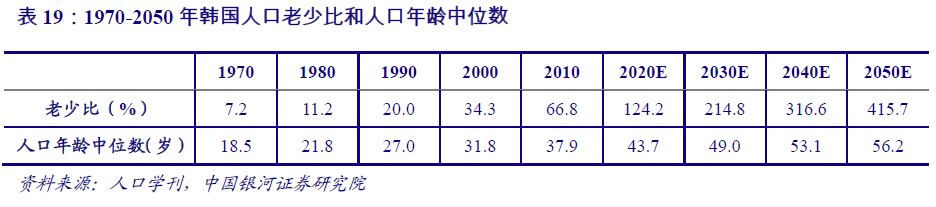

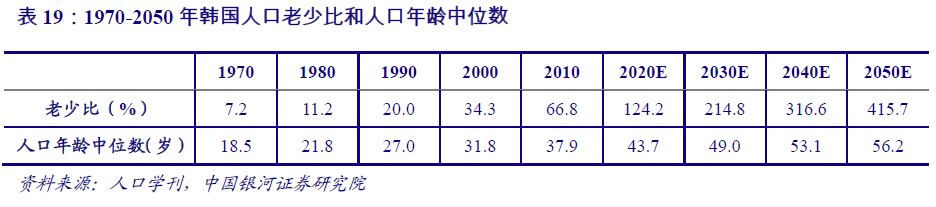

South Koreas population is aging rapidly and has entered an aging society in 2000. Comparing the time taken for the proportion of the population aged over 65 to rise from 7% to 14% of the total population, it took 24 years in Japan, 47 years in Britain, 115 years in France and only 18 years in South Korea. The main reason for the rapid aging of South Korea is that in the early 1960s, South Korea began to implement the population growth inhibition policy, the birth rate decreased from 45.7% in 1955-1960 to 16.2% in 1985, and the rapid decline of mortality, so the trend of population aging is obvious. The degree of aging can also be described by the ratio of old to young and the median age of the population (Jin duwan, Zheng Zhenzhen, 2007). The ratio of old to young is the ratio of the elderly population to the number of children, also known as the aging index. The larger the index, the more the population age structure tends to aging. The median age of the population is also one of the criteria to measure the aging. Generally, the median age of 30 is taken as the boundary of the aging of the age structure. If it is higher than 30, it is considered to be an elderly population. Taking this as the standard, South Korea has entered an aging society in 2000.

In order to adapt to the change of population structure and solve the problem of labor shortage, South Koreas industrial robot industry came into being, and famous robot enterprises such as Hyundai, robostar and dongburobot were established one after another.

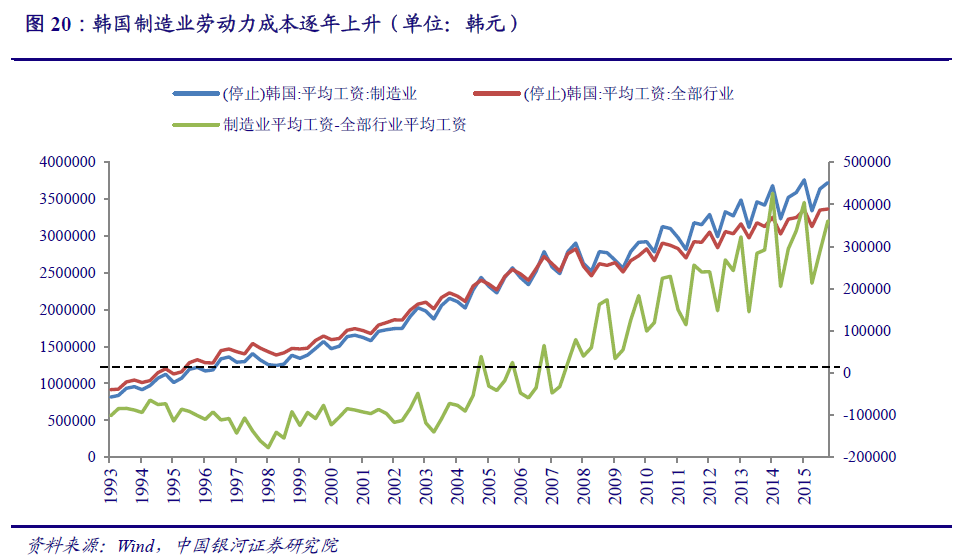

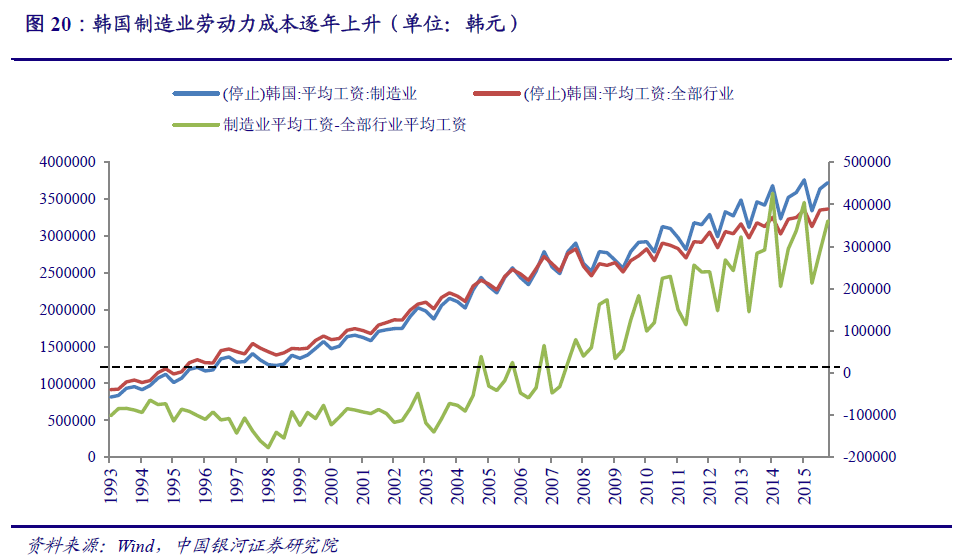

During the vigorous development of industry, there was a continuous shortage of labor, and the labor cost in South Korea increased year by year. The early development of industrial robots in South Korea did not completely solve the problem of imbalance between labor supply and demand. The continuous shortage of labor in South Korea led to the rising labor cost of manufacturing industry from 2008 to 2018. Since 2008, the average wage of the manufacturing industry has been higher than that of the industry, and the difference between the two has gradually increased. The wage of the manufacturing industry was higher than that of the industry by 174000 won / quarter in 2008, 361000 won / quarter in 2015, and CAGR was as high as 11.0%. The relative rise in wages in the manufacturing industry will promote the development of labor substitution products with high cost performance, such as industrial robots.

High labor costs and strong downstream demand ?, the industry continues to flourish.

By reviewing the early development of industrial robots in Japan, Germany and South Korea, it can be seen that when the economy continues to grow rapidly, the change of population structure is usually the main incentive to promote the automation transformation of manufacturing industry and the replacement of machines. The continuous decline in the proportion of the labor population has led to a more significant shortage of labor, further pushing up the labor cost of manufacturing industry, and promoting the rapid growth of industrial robots as a labor alternative.

1. Japan: aging population makes robots on the stage of industrial production

In 1967, Kawasaki heavy industry company introduced robots and related technologies from the United States Union, the worlds first robot enterprise, and established a production workshop. The next year, it successfully developed the first Kawasaki robot. With the improvement of Japans annual economic growth rate, Japans labor force is far from meeting the needs of rapid economic development. The emergence of industrial robots has effectively solved this problem.

From the late 1950s to 1960s, the baby boom in Japan gradually faded, the growth of Japanese labor force slowed down around 1975, and industrial robots began to sprout and develop. From 1985 to 2000, the number of industrial robots in Japan grew rapidly, from 90000 to 390000, showing a trend of rapid development in the early stage; During the period from 2000 to 2008, the number of units remained basically stable, at the level of about 350000 units; After 2008, Japans manufacturing industry gradually shifted abroad, and the downstream demand decreased, resulting in the gradual decline of the number of industrial robots in Japan.

After World War II, Japans economy grew rapidly and its production demand was strong. After the end of World War II, Japan took steel and coal as a breakthrough to restore its economy, and the United States as a model in production and consumption. Therefore, the technology needed for this purpose can be industrialized and commercialized quickly without developing from scratch and introducing advanced technology. Therefore, Japan ushered in rapid economic growth through imitation, digestion and improvement.

In 1960, Japans GDP was only US $44.3 billion, which rose to US $1105.4 billion in 1980, with a CAGR of 17.45%. During this period, the proportion of industrial added value in GDP remained at 37% - 43%, which contributed greatly to economic growth. Under the background of rapid economic growth, the demand for industrial production was so strong that the demand for labor continued to expand.

The proportion of the working population has declined, in contrast to the rapidly growing GDP. After 1945, more than 5 million young and middle-aged veterans and migrant returnees set off a baby boom in Japan. From 1945 to 1949, the birth rate reached more than 33%, which decreased slightly from 1950 to 1954, but remained at a high level of more than 20%. Overall, the average birth rate in Japan during the decade 1945-1954 was about 28%, and the average population aged 13 and under was about 27 million, accounting for 32% of the total population. This batch of baby boomers made Japans labor force population rise rapidly in the 1960s-1970s. From the late 1950s to the 1960s, the baby boom gradually faded. Therefore, from around 1975, the growth of Japans labor force began to slow down, and the proportion of labor force in the total population decreased compared with before. The decline in the proportion of labor force was in sharp contrast to the high growth rate of GDP at that time. The shortage of labor force was difficult to support Japans development policy inclined to heavy industry for a long time.

In 1969, the total population of Japan was 103.172 million, the population aged 15-64 was 71.224 million, and the proportion of labor force population reached 69.03%, ranking first in the world; In 1977, the total population was 113.863 million, and the population aged 15-64 was 7, 6.829 million, and the proportion of labor force dropped to 67.47%, ranking fifth in the world. In 1970, the proportion of the population over 65 years old in Japan has exceeded 7%. According to the new standards of the United Nations, the region is regarded as entering an aging society when the elderly aged 65 account for 7% of the total population. Therefore, Japan officially entered an aging society in 1970.

Before 1990, the proportion of Japans population aged 65 and over in the total population increased slowly, from 5.62% in 1960 to 11.87% in 1990. The slope of the fitting straight line in this time interval was 0.20. Since 1990, the proportion of the population aged 15-64 in Japan has continued to decline. At the same time, the proportion of the population aged 65 and over has increased rapidly, and the slope of the fitting straight line has changed to 0.57, which has significantly accelerated the aging rate in Japan.

The shortage of labor force, coupled with policy support, boosted the early growth of industrial robots. In the context of rapid economic growth, the demand for labor force dominated by young labor force is expanding, resulting in the trend of insufficient labor supply. The change of population structure makes the employment situation of enterprises worse. At this time, it happened that the first industrial robot "unimate" had just been born. Although the technology was not mature, it was unable to meet the production demand due to labor shortage. In addition, the Japanese government issued a number of policies to promote the popularization of industrial robots. Japanese enterprises began to use industrial robots one after another, and the number of industrial robots gradually increased rapidly.

Since the 1980s, Japans industrial robot ownership and shipment index have risen rapidly. In 1980, it was called the first year of the popularity of industrial robots in Japan. The output value increased by 85% compared with 1979, reaching 78.4 billion yen (equivalent to about 800 million yuan), and the output reached 19900 units, forming an emerging industry. In 1983, Japans industrial robot producer shipment index was 10.20 (2010 = 100), which rose to 66.50 in 1990, and CAGR was 30.71%.

At the same time, Japan had 93000 sets of industrial robots in 1985, accounting for about 70% of the worlds industrial robots. In 1990, it had 274210 sets, an increase of 194.85% in 10 years. It was the most developed country in the worlds industrial robot industry at that time.

The change of population structure leads to the shortage of labor force, which leads to the increase of labor cost in manufacturing industry, and continues to drive the steady growth of the number of industrial robots. The conflict between a large number of labor demand and the shortage of labor leads to the rapid rise of labor costs, forcing enterprises to increase the proportion of industrial robots as a solution to reduce production costs. As two countries with relatively developed industrial robot industry in the world, Japan and Germany benefit from the rise of labor cost in the second stage of industrial robot development.

The growth of labor force peaked, and the shortage of labor supply led to the continuous rise of per capita salary in the manufacturing industry. From 1980s to 1990s, Japans industrial sectors represented by coal, steel and electric power continued to develop, so there has always been a great demand for manufacturing employees. On the other hand, with the gradual progress of the technology and application of industrial robots, the number of industrial robots in Japan remained high until 2005.

On the one hand, the labor supply is weak, on the other hand, the labor demand far exceeds the total number of existing labor force in Japan. Therefore, the per capita salary growth of manufacturing employees is significantly faster than that of the number of employees. At the same time, because of the rapid development of Japanese economy and the market bubble, the salary level and the price level of the employees rose synchronously and rapidly. However, in the same period, the wage gap between manufacturing and non manufacturing industries widened significantly after 1990. We believe that the conflict between supply and demand of labor in manufacturing industry is the main reason for the surge of labor costs.

The per capita salary of manufacturing industry continued to rise, which was significantly higher than that of non manufacturing industry. In 1990, the per capita salary of manufacturing industry was 360459 yen / month and that of non manufacturing industry was 321402 yen / month. The difference between the two was only 39057 yen / month (the exchange rate in 1990 was about 100 yen to 4 yuan). The per capita salary of manufacturing industry was 12.15% higher than that of non manufacturing industry. Subsequently, the gap continued to expand. In 1995, the per capita salary gap between manufacturing and non manufacturing industries was as high as 42674 yen / month, and the per capita salary of manufacturing industry was 12.30% higher than that of non manufacturing industry; In 2000, the per capita salary of manufacturing industry was 393174 yen / month and that of non manufacturing industry was 327039 yen / month, with a gap of 66%, 135 yen / month, the per capita salary of manufacturing industry is 20.22% higher than that of non manufacturing industry.

After 2007, the more mature industrial robot technology and the higher cost performance brought by the use of robots have solved the labor demand of enterprises. During this period, due to the impact of the financial crisis, the per capita salary of manufacturing employees gradually decreased to about 320000 yen / month, and the gap between the per capita salary of manufacturing employees and non manufacturing employees gradually decreased and remained at 50000 yen / month. From the reasons of salary changes before 2006, the rapid growth of salary before 1990 was caused by the decline of the proportion of employed population, which led to the salary growth of manufacturing industry and non manufacturing industry almost at the same pace. After 1990, the salary shock of manufacturing industry rose, while the salary growth of non manufacturing industry slowed down and gradually decreased, and the salary gap between manufacturing industry and non manufacturing industry gradually widened, The salary difference will gradually transfer the labor force to the manufacturing industry with high salary. At the same time, it will also promote the development of labor substitution products with high cost performance such as industrial robots.

The increase of labor cost makes the demand of industrial production more and more urgent, and promotes the great leap forward development of industrial robots. On the one hand, due to the squeeze of higher labor costs on the companys profit space, Japanese enterprises have chosen to continue to expand the use of industrial robots to reduce costs. On the other hand, from 1970 to 2000, industrial robots changed from hydraulic power assisted control to electric power assisted control, and gradually added visual recognition and mechanical control. Various research results have made continuous progress and have been mature and applied to industrial robot products. Therefore, the density of industrial robots in Japan has achieved leapfrog development at this stage. In 1985, the density of industrial robots in Japan was 103 units / 10000 workers, which continued to grow in the next 15 years. In 1990, 1995 and 2000, it was 282, 362 and 385 units / 10000 workers respectively.

The transfer of labor-intensive industries, the number of industrial robots in Japan stagnated. Different from most countries, due to its geographical environment and comprehensive consideration of economy, Japan gradually transferred its domestic labor-intensive industries to China and other Southeast Asian countries with low labor cost at the end of the 20th century and the beginning of the 21st century. During this period, the proportion of Japans domestic manufacturing industry in GDP also decreased, In addition, the financial crisis in 2008 led to a sharp plunge in the per capita salary of the manufacturing industry. The growth of the number of industrial robots brought by labor shortage in Japan basically peaked. The density of industrial robots in Japan reached its peak in 2005 (409 sets / 10000 workers). In recent ten years, the supply and demand of labor have been in a relatively balanced state, and the density of industrial robots has stabilized at about 330 sets / 10000 workers.

2. Germany: conflict between industrial manufacturing power and high labor cost

Similar to Japan, the changes in population structure and labor costs are relatively high, driving the vigorous development of German industrial robots. The reason why German manufacturing dominates the world is that Germany has a very high level of robot automation application. As early as the 1980s, Germany began the process of "machine replacement". The number of industrial robots in Germany has been steadily increasing year by year.

German industrial robots started to develop in the 1980s. From 1985 to 2000, the number of industrial robots in Germany increased rapidly, from 8800 to 91184, and the CAGR reached 16.87%; After 2000, the change of population structure accelerated, superimposed with the increase of labor cost, and the number of industrial robots in Germany continued to grow steadily. In 2015, the number of industrial robots increased to 183000, and the CAGR was 4.75%.

Around 2000, the change of German population structure accelerated, giving birth to the development of industrial robots. Since 2000, the aging rate in Germany has accelerated significantly. While the proportion of the population aged 65 and over has increased, the proportion of the labor force has declined rapidly. The change of population structure has given birth to the development of industrial robots as an incentive.

With the expansion of German manufacturing industry, the demand for labor has expanded accordingly. In the 1990s, the German government and enterprises attached great importance to promoting the adjustment of industrial structure through technological progress. In 1995, Germany issued the "manufacturing technology 2000 framework plan", taking "using information and communication technology to promote the modernization of manufacturing industry" as the main goal of the plan, and successfully realized industrial expansion. In 2000, the added value of German manufacturing industry was 433.3 billion euros, and in 2010, the added value of German manufacturing industry was 5, 05.1 billion euros, an increase of 17% over the past decade, and the demand for labor has increased accordingly; The labor force population in Germany was 40.44 million in 2000 and 42.47 million in 2010, an increase of only 5.0% over the past decade. The high growth rate of manufacturing added value is in strong contrast to the slow growth of the labor force population.

Germanys labor market is in short supply, driving up labor costs. Labor shortage follows the change of population structure and is directly reflected in the salary level of manufacturing employees. In 1996, the cost of industrial labor in Germany was 24 euros / hour and that in the EU was 14.8 euros / hour. The cost of industrial labor in Germany was 62% higher than that in the EU. The high labor cost forced German enterprises to replace labor with industrial robots.

With the gradual popularization of industrial robots, although the labor cost in Germany is still rising, the gap between Germany and the EU is gradually narrowing. In 2000, the labor cost in Germany was 55% higher than the EU average level, and the gap was reduced to 35% in 2010, and then gradually stabilized. In this ratio, the penetration of industrial robots has slowed down the rapid rise of labor cost to a certain extent.

The increase in labor costs in Germany has driven the increase in the number of industrial robots. Labor intensive industries such as automobile, machinery manufacturing, chemical industry, medicine, electronics and electrical appliances are the four traditional pillar industries in Germany. Germany firmly occupies the high-end position in the global industrial chain. In the 1990s, Germanys rising labor costs occupied the profit space of enterprises. On the one hand, in order to reduce production costs, on the other hand, in order to establish the golden signboard of "made in Germany", German enterprises continued to expand the application of industrial robots in the above industries. The number of industrial robots in Germany was 91184 in 2000, 148256 in 2010, and CAGR reached 5.0%; In 2010, the global number of industrial robots was 1059, 162 sets, with Germany accounting for 14%. The great changes in population structure, the increase in employee salary and the increase in labor cost are the driving forces for Germany to continuously promote the replacement of labor force by industrial robots and realize the great leap forward development of industrial robots. Now these factors still drive the development of industrial robots in Germany.

3. Korea: high aging & amp; Low Fertility Society promotes the development of robot industry

Reviewing the development history of industrial robots in Korea, we can find that around 1990 is the key time point for the development of its robot industry, and there is a contradiction between a large number of industrial production and labor demand. Similar to Japan, the emergence of industrial robots in South Korea in the 1990s also provided an opportunity for the conflict between rapid economic growth and population structure change.

In 1990, industrial robots in South Korea began to develop, and then their ownership continued to grow rapidly. From 1990 to 2000, under the influence of the contradiction between rapid GDP growth and population aging, the number of industrial robots increased from 3020 to 37988, and the CAGR was as high as 28.81%. By 2018, the number of industrial robots in South Korea reached 300000. Benefit from Korean auto & amp; With the development of 3C industry, the demand for industrial robots is high. After 2010, the growth rate of industrial robots in South Korea remains at a high level.

Adjusting the export-oriented economic development strategy, South Koreas GDP increased rapidly. In the early 1960s, South Korea actively pursued the export-oriented economic development strategy, vigorously promoted the processing industry, increased exports and earned foreign exchange, quickly got rid of poverty and backwardness, and accelerated industrialization and modernization. After the 1990s, in order to transform its original government led export-oriented economy into a market-oriented export-oriented economy and optimize the industrial structure, South Korea carried out a new round of adjustment of its export-oriented economic development strategy, made use of the opportunity of industrial transfer from developed countries, combined with its national conditions, vigorously introduced advanced technology, and realized the transformation of industrial structure from capital intensive to technology Knowledge intensive upgrading has ushered in rapid economic growth.

In 1990, the total GDP of South Korea was 191.38 trillion won, the per capita GDP was 6516 US dollars, and that of China was 317 US dollars. The per capita GDP of South Korea was about 21 times that of China. In 2000, the total GDP of South Korea increased to 651.63 trillion won, with a compound growth rate of 13%.

In the 1970s, South Korea implemented two five-year plans, aiming at shipbuilding, automobile production, steel, chemical industry and other heavy industries. The development of heavy industry has brought unprecedented speed to South Koreas economic development. Subsequently, South Korea mainly relied on exports to promote its economic growth. Manufactured products such as electronics, ships, automobiles and steel were its most important export products. In 1986, Hyundai made an important decision to enter the American automobile market. The vigorous development of automobile industry provides a good opportunity for the growth of industrial robots.

With the change of population structure in South Korea, the problem of aging is becoming more and more serious. In the 1990s, South Koreas fertility rate continued to decline and the total population grew slowly, while the increasing number of people over 65 led to the rapid increase of the proportion of the elderly in the total population. In 1990, the total population of South Korea was 42.87 million, the population over 65 years old was 2.24 million, and the elderly accounted for 5.23% of the total population. In 2000, the total population of South Korea was 47.01 million, the population over 65 years old was 3.38 million, and the elderly accounted for 7.19% of the total population, which means that South Korea has officially entered the "aging society". The aging problem is becoming more and more serious due to the change of population structure. Like Japan, South Korea also has the problem of labor shortage.

South Koreas population is aging rapidly and has entered an aging society in 2000. Comparing the time taken for the proportion of the population aged over 65 to rise from 7% to 14% of the total population, it took 24 years in Japan, 47 years in Britain, 115 years in France and only 18 years in South Korea. The main reason for the rapid aging of South Korea is that in the early 1960s, South Korea began to implement the population growth inhibition policy, the birth rate decreased from 45.7% in 1955-1960 to 16.2% in 1985, and the rapid decline of mortality, so the trend of population aging is obvious. The degree of aging can also be described by the ratio of old to young and the median age of the population (Jin duwan, Zheng Zhenzhen, 2007). The ratio of old to young is the ratio of the elderly population to the number of children, also known as the aging index. The larger the index, the more the population age structure tends to aging. The median age of the population is also one of the criteria to measure the aging. Generally, the median age of 30 is taken as the boundary of the aging of the age structure. If it is higher than 30, it is considered to be an elderly population. Taking this as the standard, South Korea has entered an aging society in 2000.

In order to adapt to the change of population structure and solve the problem of labor shortage, South Koreas industrial robot industry came into being, and famous robot enterprises such as Hyundai, robostar and dongburobot were established one after another.

During the vigorous development of industry, there was a continuous shortage of labor, and the labor cost in South Korea increased year by year. The early development of industrial robots in South Korea did not completely solve the problem of imbalance between labor supply and demand. The continuous shortage of labor in South Korea led to the rising labor cost of manufacturing industry from 2008 to 2018. Since 2008, the average wage of the manufacturing industry has been higher than that of the industry, and the difference between the two has gradually increased. The wage of the manufacturing industry was higher than that of the industry by 174000 won / quarter in 2008, 361000 won / quarter in 2015, and CAGR was as high as 11.0%. The relative rise in wages in the manufacturing industry will promote the development of labor substitution products with high cost performance, such as industrial robots.

High labor costs and strong downstream demand ?, the industry continues to flourish.

By reviewing the early development of industrial robots in Japan, Germany and South Korea, it can be seen that when the economy continues to grow rapidly, the change of population structure is usually the main incentive to promote the automation transformation of manufacturing industry and the replacement of machines. The continuous decline in the proportion of the labor population has led to a more significant shortage of labor, further pushing up the labor cost of manufacturing industry, and promoting the rapid growth of industrial robots as a labor alternative.