Лазерная сварка роботом FanCheng Fanuc: новая технология лазерной сварки с высокой эффективностью, высокой скоростью

Опубликован в:2020-07-02

Robot laser flying welding technology is a new type of laser welding technology that uses robot controlled laser galvanometer for scanning welding. In the automobile manufacturing industry, laser flying welding is mainly used in automobile seat panels, instrument related parts, door structural parts, trunk lid, etc. in addition, it can also be used in different materials such as aluminum alloy, galvanized sheet and new energy battery modules Welding of plastic parts and other products.

Laser welding application of aluminum alloy in General Motors factory (source: General Motors)

Main advantages of laser flying welding:

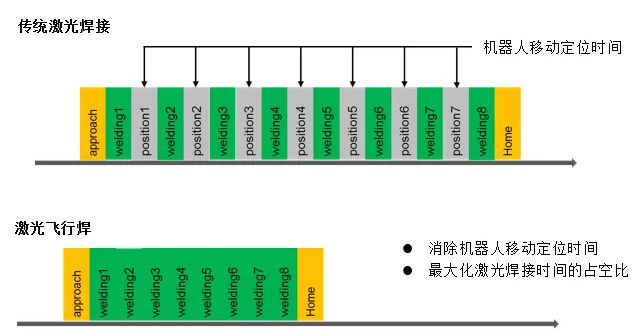

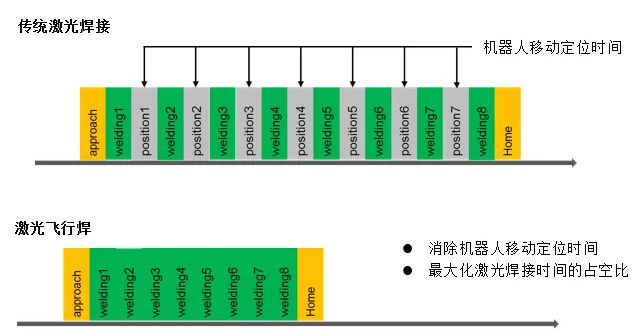

Through the close cooperation between the robot arm and the laser galvanometer, it has zero contact with the workpiece in the welding process, and the weld position can be flexible and changeable. The movement of the robot is synchronized with the scanning welding of the laser galvanometer, which can maximally eliminate the waste of non productive time caused by repeated positioning before each welding section, so as to maximize the online time of the laser beam and high production efficiency.

Robot laser flying welding solution:

Shanghai FANUC has developed and reserved the professional technology of robot laser flight welding application, which can provide users with overall laser welding solutions. Main components of robot laser flying welding:

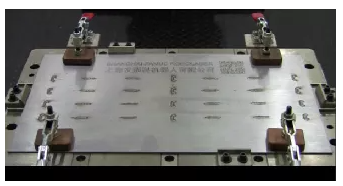

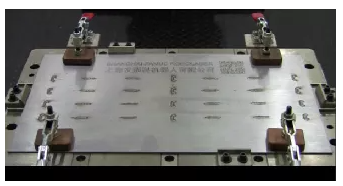

For example, aiming at the popular welding of lithium battery components, Shanghai FANUC has developed a laser remote welding system for lithium battery soft connection components, which can be widely used in the auto parts industry, such as automatic welding in power batteries, seats, doors and other fields.

Robot for FANUC laser welding:

Fanuc m-710ic series, r-1000ia series and r-2000ic series robots, with load range from 50kg to 210kg and motion radius from 2050mm to 3100mm, can meet the needs of various robot laser welding applications and provide users with diversified choices.

Fanuc robot laser flying welding technology:

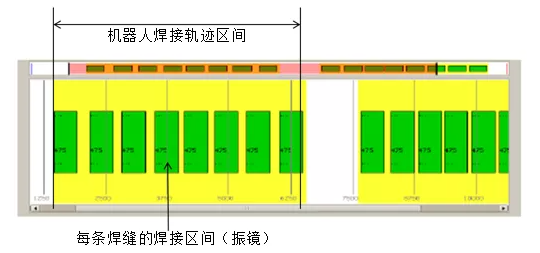

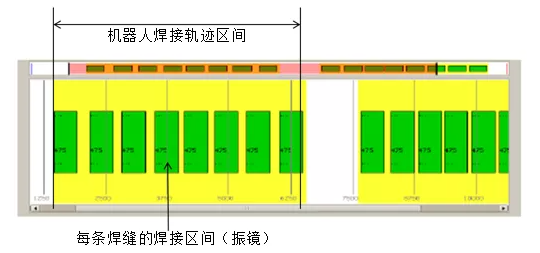

For robot laser flying welding, FANUC provides external trajectory optimization software, which can output the motion trajectory and speed curve of the robot to the galvanometer control system, so as to ensure that all welds scanned by the galvanometer are located in the welding trajectory range of the robot and realize the coordinated movement of the robot and the galvanometer.

External trajectory optimization function

Robot laser flying welding can realize high-efficiency and high-quality welding. The maximum welding speed can reach 100M / min, with high production efficiency, less heat input, small thermal deformation and higher precision of workpiece after welding. It can design welds of any shape, such as O-type, S-type and C-type, and can also be accurately designed according to the needs of actual welds.

Weld renderings

Fanuc laser:

Fanuc laser has rich product series, with laser power of 500W, 1000W, 2000W, 3000W, 4000W, 5000W and 6000W, excellent beam quality and modulation frequency of 32767hz; Perfectly compatible with FANUC control system, Ethernet communication, automatic signal distribution and special laser instructions can be adopted; It can cover laser cutting, welding, drilling, deposition, quenching and other application fields.

In the future, as more and more laser processes and markets become more mature, such as material processing, 3D printing and the development of more robot flexible laser applications, the development prospect of laser flight welding is bound to be brighter.

Laser welding application of aluminum alloy in General Motors factory (source: General Motors)

Main advantages of laser flying welding:

Through the close cooperation between the robot arm and the laser galvanometer, it has zero contact with the workpiece in the welding process, and the weld position can be flexible and changeable. The movement of the robot is synchronized with the scanning welding of the laser galvanometer, which can maximally eliminate the waste of non productive time caused by repeated positioning before each welding section, so as to maximize the online time of the laser beam and high production efficiency.

Robot laser flying welding solution:

Shanghai FANUC has developed and reserved the professional technology of robot laser flight welding application, which can provide users with overall laser welding solutions. Main components of robot laser flying welding:

For example, aiming at the popular welding of lithium battery components, Shanghai FANUC has developed a laser remote welding system for lithium battery soft connection components, which can be widely used in the auto parts industry, such as automatic welding in power batteries, seats, doors and other fields.

Robot for FANUC laser welding:

Fanuc m-710ic series, r-1000ia series and r-2000ic series robots, with load range from 50kg to 210kg and motion radius from 2050mm to 3100mm, can meet the needs of various robot laser welding applications and provide users with diversified choices.

Fanuc robot laser flying welding technology:

For robot laser flying welding, FANUC provides external trajectory optimization software, which can output the motion trajectory and speed curve of the robot to the galvanometer control system, so as to ensure that all welds scanned by the galvanometer are located in the welding trajectory range of the robot and realize the coordinated movement of the robot and the galvanometer.

External trajectory optimization function

Robot laser flying welding can realize high-efficiency and high-quality welding. The maximum welding speed can reach 100M / min, with high production efficiency, less heat input, small thermal deformation and higher precision of workpiece after welding. It can design welds of any shape, such as O-type, S-type and C-type, and can also be accurately designed according to the needs of actual welds.

Weld renderings

Fanuc laser:

Fanuc laser has rich product series, with laser power of 500W, 1000W, 2000W, 3000W, 4000W, 5000W and 6000W, excellent beam quality and modulation frequency of 32767hz; Perfectly compatible with FANUC control system, Ethernet communication, automatic signal distribution and special laser instructions can be adopted; It can cover laser cutting, welding, drilling, deposition, quenching and other application fields.

In the future, as more and more laser processes and markets become more mature, such as material processing, 3D printing and the development of more robot flexible laser applications, the development prospect of laser flight welding is bound to be brighter.