Прецизионный редуктор FanCheng Nabotesk RV открывает больше возможностей -- серия GH

Опубликован в:2020-07-23

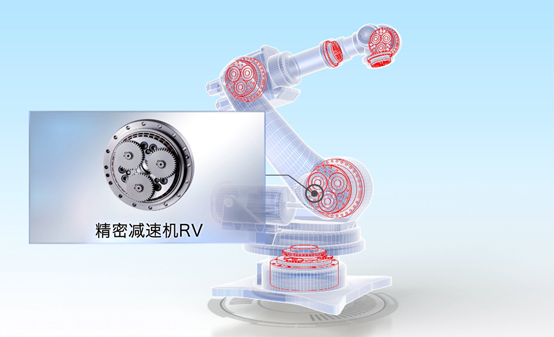

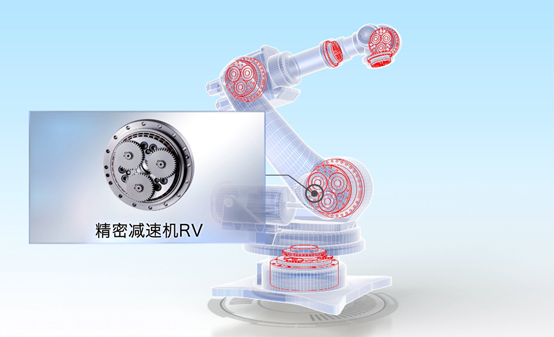

When talking about nabotsks precision reducer RV, everyone will think that it can be used in the joint parts of industrial robots. By converting small power into large energy, precision action is realized. And it has the characteristics of light weight, small volume, high rigidity and superior durability, which has been recognized by the industry.

But in fact, the precision reducer RV can also be used in a wide range of fields other than industrial robots.

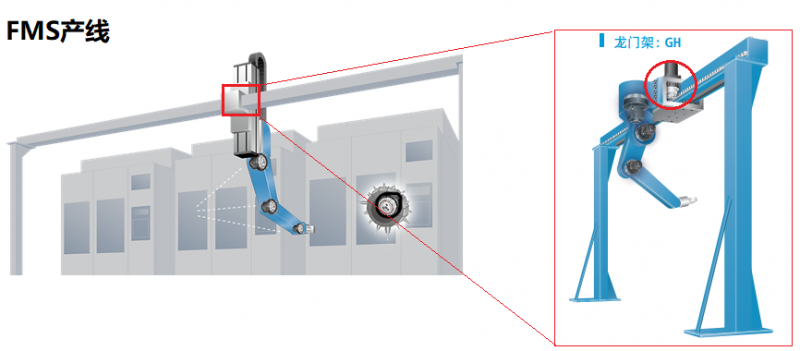

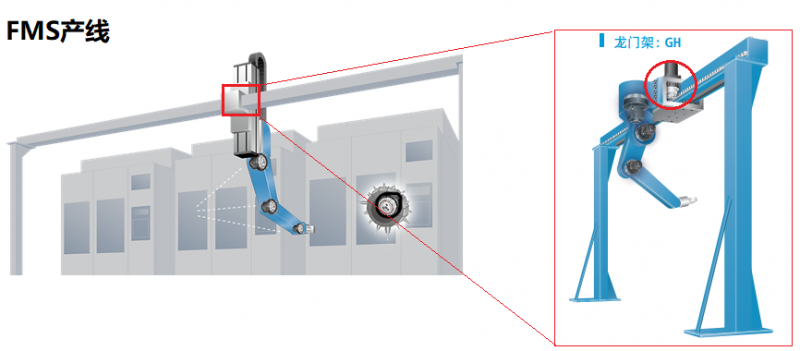

For example, it is applicable to industrial automation fields such as FMS production line and welding equipment.

FMS production line (flexible automatic production line) is a production line composed of multiple adjustable machine tools and automatic conveying devices. With the upgrading of industrial automation, higher requirements are put forward for FMS production line, such as the accuracy and rigidity of automatic transportation manipulator, the space cost of equipment and so on. Nabotesks precision reducer products can perfectly solve these problems.

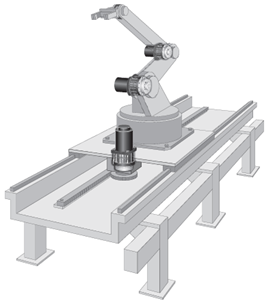

GH series reducer can perfectly solve the problems of rigidity and accuracy of robot walking shaft. In order to directly support large loads, GH series is equipped with large angular contact ball bearings. It adopts double support mechanism and needle wheel mechanism, and the product will not be damaged even when the torque up to 7 times of the rated torque is applied. It has the characteristics of high rigidity, small backlash and high torque density. It can realize high-speed output with low reduction ratio and greatly improve the working efficiency of the equipment. It is a high-speed gear head that can give full play to the ability of servo motor in many fields such as walking shaft, lifting shaft and so on. The reducer has been sealed with special grease when leaving the factory, which is convenient for users to install and use. According to different connection modes of equipment, flange output type or shaft output type can be freely selected.

Gh-p series flange output type:

Gh-s series shaft output type:

GH series is also applicable to the following scenarios

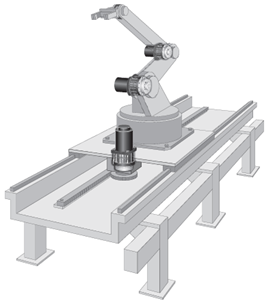

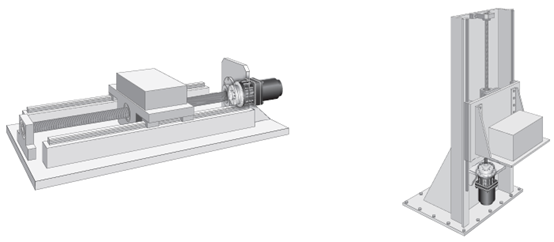

Robot walking axis:

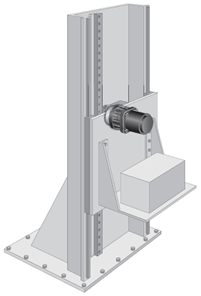

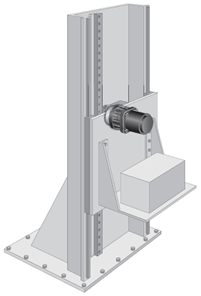

Loader lifting shaft:

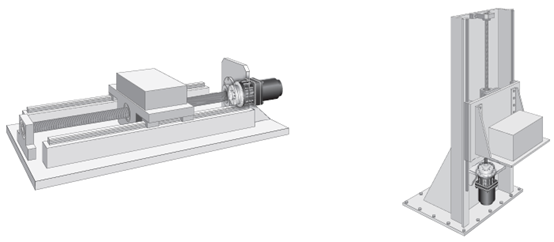

Ball screw drive shaft:

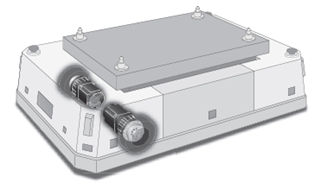

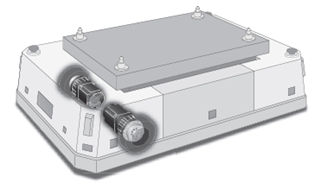

AGV drive and control shaft:

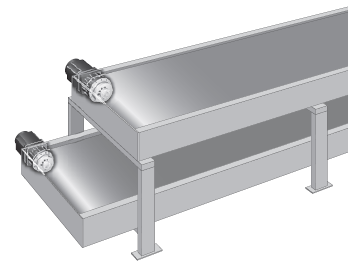

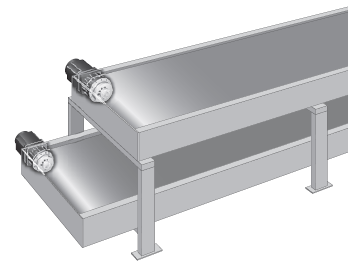

Conveyor:

But in fact, the precision reducer RV can also be used in a wide range of fields other than industrial robots.

For example, it is applicable to industrial automation fields such as FMS production line and welding equipment.

FMS production line (flexible automatic production line) is a production line composed of multiple adjustable machine tools and automatic conveying devices. With the upgrading of industrial automation, higher requirements are put forward for FMS production line, such as the accuracy and rigidity of automatic transportation manipulator, the space cost of equipment and so on. Nabotesks precision reducer products can perfectly solve these problems.

GH series reducer can perfectly solve the problems of rigidity and accuracy of robot walking shaft. In order to directly support large loads, GH series is equipped with large angular contact ball bearings. It adopts double support mechanism and needle wheel mechanism, and the product will not be damaged even when the torque up to 7 times of the rated torque is applied. It has the characteristics of high rigidity, small backlash and high torque density. It can realize high-speed output with low reduction ratio and greatly improve the working efficiency of the equipment. It is a high-speed gear head that can give full play to the ability of servo motor in many fields such as walking shaft, lifting shaft and so on. The reducer has been sealed with special grease when leaving the factory, which is convenient for users to install and use. According to different connection modes of equipment, flange output type or shaft output type can be freely selected.

Gh-p series flange output type:

Gh-s series shaft output type:

GH series is also applicable to the following scenarios

Robot walking axis:

Loader lifting shaft:

Ball screw drive shaft:

AGV drive and control shaft:

Conveyor: