Кодировщик комплекта полого вала FanCheng Position frabas может использоваться для манипуляторов роботов

Опубликован в:2020-07-31

For robot designers and suppliers, space and power are always extremely valuable. Although current controllers typically require two single turn encoders working in parallel and a synchronous gearbox, the new hollow shaft kit encoder of positional fraba can do this on its own.

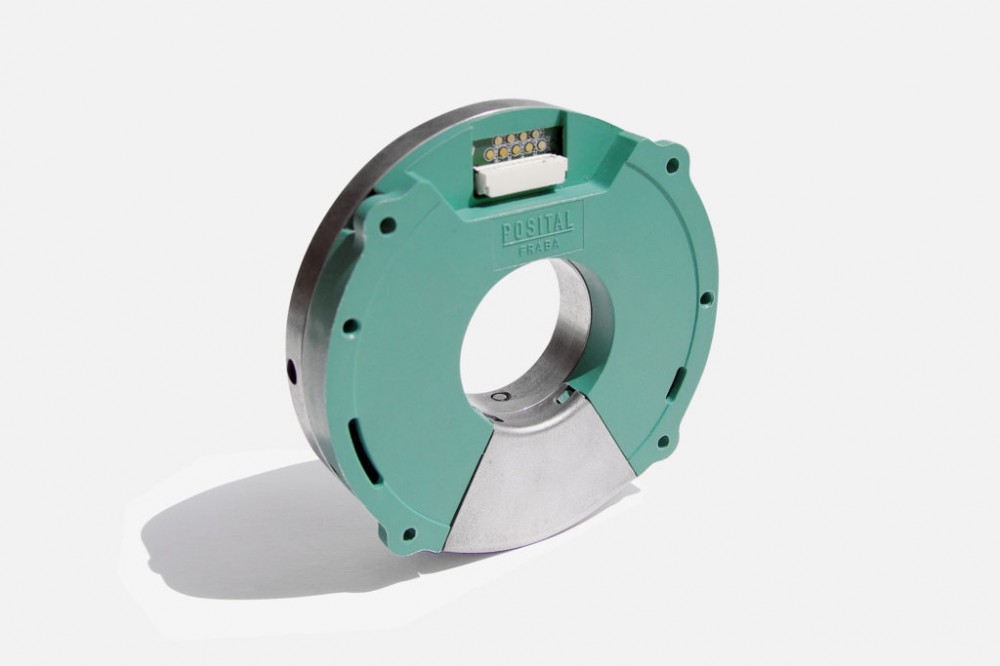

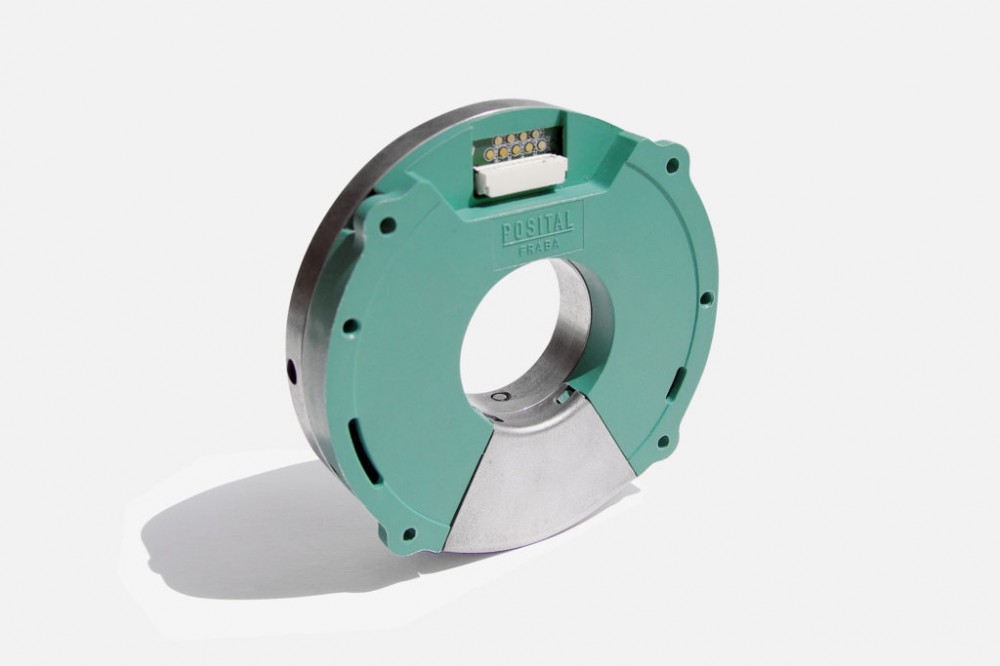

Hollow shaft kit encoder

Hollow shaft encoders with ring and open center design are very useful in robots. They can be installed directly inside the joint to measure the position of the arm. According to posital fraba in Cologne, Germany, most hollow shaft encoders are single turn equipment.

Controller and sensor manufacturers claim that their new capacitive hollow shaft kit encoder has overcome this limitation. According to posital, they integrate an integrated rotation counter that records each rotation - no external power, easy to maintain batteries or complex gears.

This self-sufficiency is made possible by the Wiegand energy collection system that posital has provided for many years in its conventional encoders and kit encoders. The technology of converting rotary motion into electric pulse has been adapted to the design of hollow shaft.

The company said that hollow shaft encoders are also very useful for servo motors, drives and other rotating machinery because their ring shape makes it easy to install around the shaft.

Hollow shaft kit designed to facilitate robot installation

Positional fraba said that its hollow shaft kit encoder is very suitable for robotics, from six axis industrial robots to lighter and more agile cooperative robots.

The hollow shaft kit can be installed directly inside the joint to monitor and control the three-dimensional motion of the robot arm. This application requires high accuracy - the working accuracy of modern industrial robots is as high as 0.1mm.

For cooperative robots and traditional articulated robots, the center hole (30 or 50 mm) of the hollow shaft kit can be used to route cables and dielectric hoses in the housing.

Posital said that the slim design (with a depth of only 17.8mm, an outer diameter of 80mm and a weight of only 110g) made installation easy. It says just a few simple steps and screws are enough. These devices also have a self calibration function to ensure accurate results in the shortest setting time.

The hollow shaft kit encoder is designed for industrial robots and cooperative robot arms. Source: posital

Capacitance measurement substitution

Although positional fraba has been in a leading position in the transition from optical encoder technology to magnetic encoder technology, it indicates that it has chosen another way for the hollow shaft series. Because it is difficult to realize the magnetic system in the design of hollow shaft, the capacitance measurement technology is the first choice.

The capacitive encoder is composed of rotor and stator components, which are shaped like flat rings with specially patterned conductive surfaces and can be used as capacitor plates. As the rotor rotates, these surfaces change their relative positions, thus changing the capacitive coupling of the whole system. This will modulate the amplitude and phase angle of the high-frequency electrical signal transmitted through the capacitor system.

These signal changes are captured and decoded by a special ASIC processor to determine the angular position of the rotor with high precision. The measurement results are transmitted to the central controller through the open source SSI or BISS C interface. The capacitance is averaged over the entire circumference of the annular rotor and stator assembly, so the system is relatively unaffected by small alignment errors or moisture or dust.

Capacitor surfaces on stator and rotor assemblies. Source: posital

The key of multi rotation system is a special energy collector based on Wigan effect. The mechanical motion is captured as magnetic energy in the Wigan wire and then released as electrical pulses to power the rotating counter. Traditional Wigan harvesters rely on permanent magnets installed on the center line of the drive shaft, and a new device must be found for the design of hollow shaft.

Located in the R & D center in Aachen, Germany, positional fraba has developed the arrangement of four permanent magnets installed on the circumference of the rotor through more than one year of field test and strong magnetic field simulation.

These magnets produce a stable magnetic field, which can be detected and used by Wigan sensors installed in the stator. Every 360 ° rotation of the magnet on the rotor, the tiny Wigan wire embedded in the copper coil will generate a current pulse, so as to activate the counting electronic equipment and accurately record each revolution. The multi turn counter has a 43 bit memory, which can provide a measurement range of nearly 9 trillion revolutions.

"Wigan effect" to achieve energy collection

The energy collection component collects the required power directly from the surrounding environment. The result is energy self-sufficiency – no maintenance, no batteries. Through industrial Internet of things (iiot) or industrial4. 0 setting, the theme has clearly gained momentum, involving a huge network of sensors and actuators that need to be as self-sufficient as possible.

Posital pointed out that although piezoelectric systems, thermal and dynamic processes have long limited the pace of energy collection, the Wigan effect named after American inventor John Wiegand is still considered a strange alternative.

At the heart of the Wiegand system is a small section of specially conditioned vicalloy wire, which was patented in 1972. At the end of the complex manufacturing process involving cold forming and tempering, the conductor exposes a soft core surrounded by a hard magnetic layer.

Posital said that a special function of this combination is that when the Wigan wire is exposed to a changing external magnetic field, the magnetic polarity of the wire will suddenly "flip". When this happens, a current pulse is generated in the thin copper coil wound on the conductor.

Wigan sensor. Source: posital

Since 2005, posital has been using this technology, which uses the Wiegand sensor as the power supply for the electronic rotation counter in the companys magnetic multi turn encoder. The decisive factor for the breakthrough in energy collection is the availability of ultra-efficient and low-power chips.

The company says the Wigan effect is pure energy collection. Magnetic induction energy comes directly from rotational motion. A generator can produce energy at a very different level than a constant one. The "micro power plant" is only 15 mm long, but the energy generated is 7 V or 190 NJ, which is enough to reliably activate modern rotary counters and related electronic devices.

Posital says it can produce 1 million compact Wiegand modules per year for commercial use. These consist of short wires and are surrounded by thin copper coils fitted with SMD frames.

Positional fraaba said that efforts are being made to improve the energy consumption of Wiegand sensors in other applications. At present, the test selectivity of Aachen R & D center reaches 10V. The company said that this may be close to the power level that can achieve ultra-low power electronic devices, wireless communication or radio solutions.

Hollow shaft kit encoder

Hollow shaft encoders with ring and open center design are very useful in robots. They can be installed directly inside the joint to measure the position of the arm. According to posital fraba in Cologne, Germany, most hollow shaft encoders are single turn equipment.

Controller and sensor manufacturers claim that their new capacitive hollow shaft kit encoder has overcome this limitation. According to posital, they integrate an integrated rotation counter that records each rotation - no external power, easy to maintain batteries or complex gears.

This self-sufficiency is made possible by the Wiegand energy collection system that posital has provided for many years in its conventional encoders and kit encoders. The technology of converting rotary motion into electric pulse has been adapted to the design of hollow shaft.

The company said that hollow shaft encoders are also very useful for servo motors, drives and other rotating machinery because their ring shape makes it easy to install around the shaft.

Hollow shaft kit designed to facilitate robot installation

Positional fraba said that its hollow shaft kit encoder is very suitable for robotics, from six axis industrial robots to lighter and more agile cooperative robots.

The hollow shaft kit can be installed directly inside the joint to monitor and control the three-dimensional motion of the robot arm. This application requires high accuracy - the working accuracy of modern industrial robots is as high as 0.1mm.

For cooperative robots and traditional articulated robots, the center hole (30 or 50 mm) of the hollow shaft kit can be used to route cables and dielectric hoses in the housing.

Posital said that the slim design (with a depth of only 17.8mm, an outer diameter of 80mm and a weight of only 110g) made installation easy. It says just a few simple steps and screws are enough. These devices also have a self calibration function to ensure accurate results in the shortest setting time.

The hollow shaft kit encoder is designed for industrial robots and cooperative robot arms. Source: posital

Capacitance measurement substitution

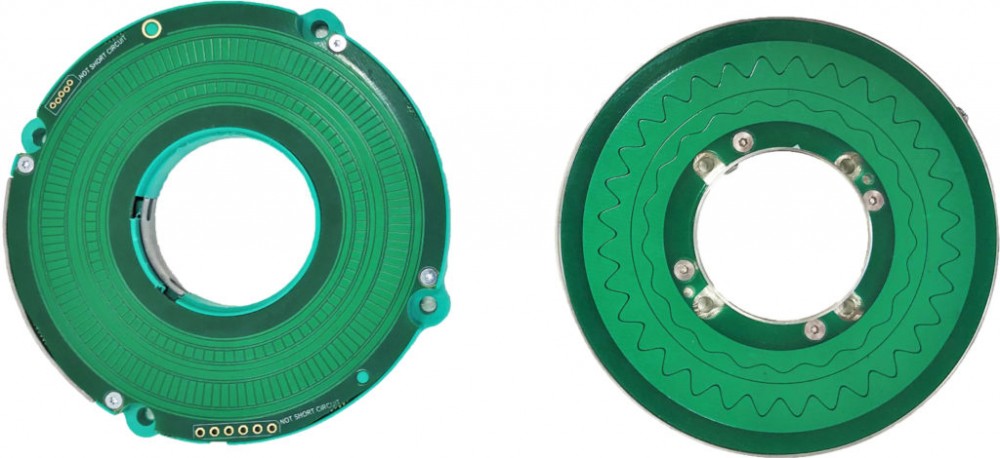

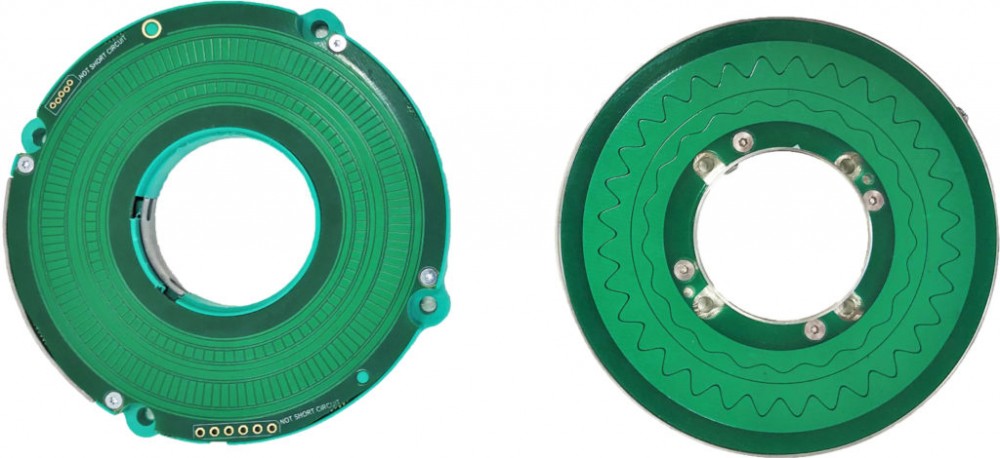

Although positional fraba has been in a leading position in the transition from optical encoder technology to magnetic encoder technology, it indicates that it has chosen another way for the hollow shaft series. Because it is difficult to realize the magnetic system in the design of hollow shaft, the capacitance measurement technology is the first choice.

The capacitive encoder is composed of rotor and stator components, which are shaped like flat rings with specially patterned conductive surfaces and can be used as capacitor plates. As the rotor rotates, these surfaces change their relative positions, thus changing the capacitive coupling of the whole system. This will modulate the amplitude and phase angle of the high-frequency electrical signal transmitted through the capacitor system.

These signal changes are captured and decoded by a special ASIC processor to determine the angular position of the rotor with high precision. The measurement results are transmitted to the central controller through the open source SSI or BISS C interface. The capacitance is averaged over the entire circumference of the annular rotor and stator assembly, so the system is relatively unaffected by small alignment errors or moisture or dust.

Capacitor surfaces on stator and rotor assemblies. Source: posital

The key of multi rotation system is a special energy collector based on Wigan effect. The mechanical motion is captured as magnetic energy in the Wigan wire and then released as electrical pulses to power the rotating counter. Traditional Wigan harvesters rely on permanent magnets installed on the center line of the drive shaft, and a new device must be found for the design of hollow shaft.

Located in the R & D center in Aachen, Germany, positional fraba has developed the arrangement of four permanent magnets installed on the circumference of the rotor through more than one year of field test and strong magnetic field simulation.

These magnets produce a stable magnetic field, which can be detected and used by Wigan sensors installed in the stator. Every 360 ° rotation of the magnet on the rotor, the tiny Wigan wire embedded in the copper coil will generate a current pulse, so as to activate the counting electronic equipment and accurately record each revolution. The multi turn counter has a 43 bit memory, which can provide a measurement range of nearly 9 trillion revolutions.

"Wigan effect" to achieve energy collection

The energy collection component collects the required power directly from the surrounding environment. The result is energy self-sufficiency – no maintenance, no batteries. Through industrial Internet of things (iiot) or industrial4. 0 setting, the theme has clearly gained momentum, involving a huge network of sensors and actuators that need to be as self-sufficient as possible.

Posital pointed out that although piezoelectric systems, thermal and dynamic processes have long limited the pace of energy collection, the Wigan effect named after American inventor John Wiegand is still considered a strange alternative.

At the heart of the Wiegand system is a small section of specially conditioned vicalloy wire, which was patented in 1972. At the end of the complex manufacturing process involving cold forming and tempering, the conductor exposes a soft core surrounded by a hard magnetic layer.

Posital said that a special function of this combination is that when the Wigan wire is exposed to a changing external magnetic field, the magnetic polarity of the wire will suddenly "flip". When this happens, a current pulse is generated in the thin copper coil wound on the conductor.

Wigan sensor. Source: posital

Since 2005, posital has been using this technology, which uses the Wiegand sensor as the power supply for the electronic rotation counter in the companys magnetic multi turn encoder. The decisive factor for the breakthrough in energy collection is the availability of ultra-efficient and low-power chips.

The company says the Wigan effect is pure energy collection. Magnetic induction energy comes directly from rotational motion. A generator can produce energy at a very different level than a constant one. The "micro power plant" is only 15 mm long, but the energy generated is 7 V or 190 NJ, which is enough to reliably activate modern rotary counters and related electronic devices.

Posital says it can produce 1 million compact Wiegand modules per year for commercial use. These consist of short wires and are surrounded by thin copper coils fitted with SMD frames.

Positional fraaba said that efforts are being made to improve the energy consumption of Wiegand sensors in other applications. At present, the test selectivity of Aachen R & D center reaches 10V. The company said that this may be close to the power level that can achieve ultra-low power electronic devices, wireless communication or radio solutions.