Модель FanCheng и руководство по выбору специального редуктора для мобильного робота

Опубликован в:2020-08-03

In the internal structure of mobile robot, reducer generally acts on the wheel side of mobile robot to drive deceleration, steering, jacking or repeat actions to complete the same process. The reducer plays an important role in improving and ensuring the accuracy of the mobile robot. It can also ensure the handling quality and ensure that the robot can accurately complete the handling task in production.

Another function of reducer in mobile robot is to transmit greater torque. When the load is large, it is not cost-effective to blindly increase the power of the servo motor. The output torque can be increased through the reducer within the appropriate speed range.

Model of special reducer for mobile robot

The main requirements of mobile robot for reducer are short length and large radial load. The second is high precision. Precision reducer is an indispensable part for reliable and accurate operation of industrial robot. Therefore, at present, the reducers used for mobile robots in the market are mainly divided into two categories: AGV special precision planetary reducer and AGV special cycloidal pin gear reducer.

Precision planetary reducer has the advantages of compact structure, small return clearance, high precision, long service life and large rated output torque. However, the processing accuracy of materials and parts is high, the structure is complex and it is difficult to manufacture and install.

Cycloid reducer is a novel transmission device with cycloid pin tooth meshing based on planetary transmission principle. It has the advantages of small volume, light weight, high action transmission accuracy, large transmission ratio range, large transmission torque, high transmission efficiency, long service life and simple structure. However, the manufacturing process of cycloid reducer is complex, and the manufacturing accuracy and assembly process requirements of some parts are high.

In addition to the above two categories, the reducer customized and developed according to the application requirements of mobile robots also accounts for part of the mobile robot market. For example, the jacking reducer specially customized for jacking AGV is decelerated by internally provided gears, and then raised and lowered by screw.

Selection guide of special reducer for mobile robot

In terms of model selection, AGV manufacturers not only select different types of reducers according to the needs of reducers, but also pay attention to the reduction ratio, installation mode, size, accuracy and stress of reducers. According to these requirements, various fault analysis of mobile robot has attracted more and more attention. For example, oil leakage is one of the more common faults, and the oil leakage of robot mainly comes from two aspects: motor oil leakage and reducer oil leakage. Among them, the phenomenon of oil leakage of reducer is more common, and the reasons behind it are related to the unreasonable installation of ontology enterprises. Therefore, the selection of installation mode is very important for AGV manufacturers, and it is also the focus of R & D direction of reducer enterprises. In addition, the requirements of AGV and related robots for the reducer also include high reliability, low noise, long life, maintenance free, etc.

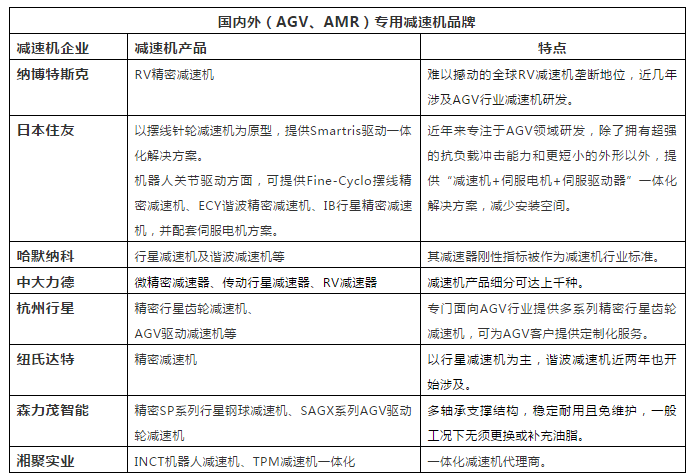

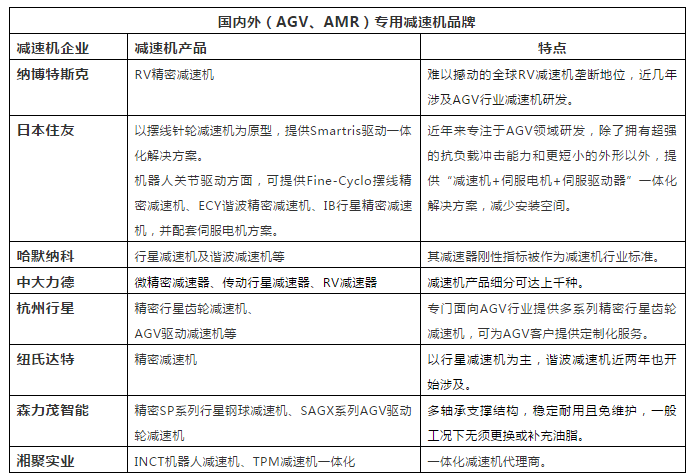

In the selection of mobile robot reducer brands, the mainstream brands in the mobile robot industry are in the domestic and foreign camps. The advantages of domestic brands lie in localization, cost performance and customized services, while the technical advantages of foreign brands can not be ignored. Representative enterprises such as nabotsk, etc.

Market status of mobile robot reducer at home and abroad

The above are enterprises involved in the research and development of AGV special reducer. This table makes rough statistics. If there is anything wrong, please correct it!

Another function of reducer in mobile robot is to transmit greater torque. When the load is large, it is not cost-effective to blindly increase the power of the servo motor. The output torque can be increased through the reducer within the appropriate speed range.

Model of special reducer for mobile robot

The main requirements of mobile robot for reducer are short length and large radial load. The second is high precision. Precision reducer is an indispensable part for reliable and accurate operation of industrial robot. Therefore, at present, the reducers used for mobile robots in the market are mainly divided into two categories: AGV special precision planetary reducer and AGV special cycloidal pin gear reducer.

Precision planetary reducer has the advantages of compact structure, small return clearance, high precision, long service life and large rated output torque. However, the processing accuracy of materials and parts is high, the structure is complex and it is difficult to manufacture and install.

Cycloid reducer is a novel transmission device with cycloid pin tooth meshing based on planetary transmission principle. It has the advantages of small volume, light weight, high action transmission accuracy, large transmission ratio range, large transmission torque, high transmission efficiency, long service life and simple structure. However, the manufacturing process of cycloid reducer is complex, and the manufacturing accuracy and assembly process requirements of some parts are high.

In addition to the above two categories, the reducer customized and developed according to the application requirements of mobile robots also accounts for part of the mobile robot market. For example, the jacking reducer specially customized for jacking AGV is decelerated by internally provided gears, and then raised and lowered by screw.

Selection guide of special reducer for mobile robot

In terms of model selection, AGV manufacturers not only select different types of reducers according to the needs of reducers, but also pay attention to the reduction ratio, installation mode, size, accuracy and stress of reducers. According to these requirements, various fault analysis of mobile robot has attracted more and more attention. For example, oil leakage is one of the more common faults, and the oil leakage of robot mainly comes from two aspects: motor oil leakage and reducer oil leakage. Among them, the phenomenon of oil leakage of reducer is more common, and the reasons behind it are related to the unreasonable installation of ontology enterprises. Therefore, the selection of installation mode is very important for AGV manufacturers, and it is also the focus of R & D direction of reducer enterprises. In addition, the requirements of AGV and related robots for the reducer also include high reliability, low noise, long life, maintenance free, etc.

In the selection of mobile robot reducer brands, the mainstream brands in the mobile robot industry are in the domestic and foreign camps. The advantages of domestic brands lie in localization, cost performance and customized services, while the technical advantages of foreign brands can not be ignored. Representative enterprises such as nabotsk, etc.

Market status of mobile robot reducer at home and abroad

The above are enterprises involved in the research and development of AGV special reducer. This table makes rough statistics. If there is anything wrong, please correct it!