Роботизированная технология FanCheng ускоряет разработку технологии обработки поверхности автозапчастей в Китае.

Опубликован в:2020-07-15

With the development of industrial robots and the emergence of new technologies such as industrial Internet, the application scope of robot electrostatic spraying and laser surface treatment is becoming wider and wider. Therefore, the overall technical level of domestic automobile parts surface treatment is accelerating.

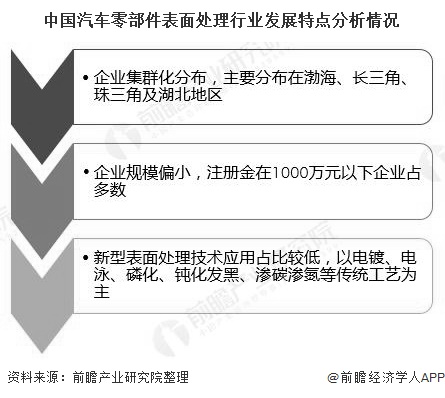

1. Cluster development of enterprises in Chinas auto parts surface treatment industry

At present, there are more than 1000 enterprises engaged in the surface treatment of auto parts in China. The enterprises are mainly distributed in the Bohai rim, Yangtze River Delta, Pearl River Delta and central Hubei, showing a certain cluster effect.

From the perspective of enterprise scale, the industry is mainly small and medium-sized enterprises. Among the enterprises engaged in the surface treatment of auto parts, most of them have a registered capital of less than 10 million yuan.

At present, the surface treatment technologies of domestic auto parts surface treatment enterprises are still dominated by traditional electroplating, electrophoresis, phosphating, passivation and blackening, carburizing and nitriding, and the application proportion of new surface treatment technologies such as high-energy beam surface strengthening, plasma spraying, surface nano strengthening and surface composite strengthening technologies is still low, The overall technical level of the industry still has great room for improvement.

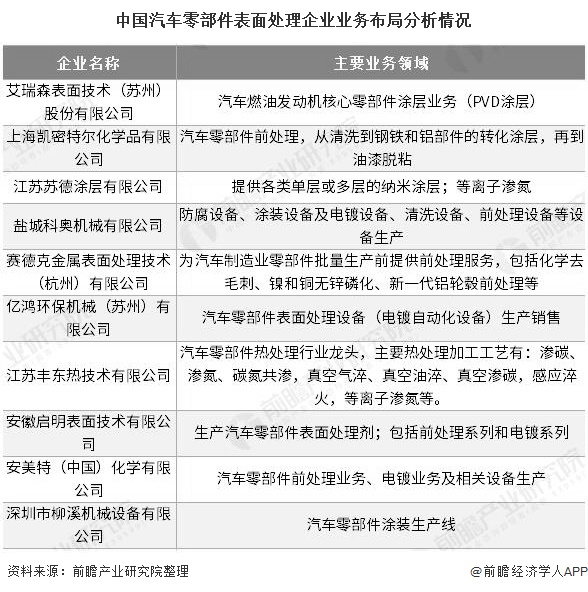

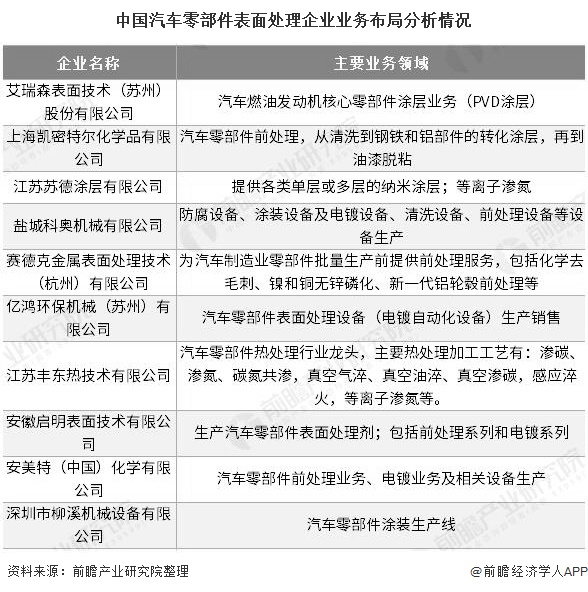

2. The business layout of Chinas auto parts surface treatment enterprises is scattered, and the industry is in a state of disorderly competition

Due to the limitation of enterprise scale, most enterprises are only engaged in one of the subdivided fields of automobile parts surface treatment, some are only engaged in the production of parts surface treatment agent, some are engaged in the pretreatment business of automobile parts, and some are engaged in the production and sales of surface treatment equipment (anti-corrosion equipment, cleaning equipment, electroplating equipment, etc.). On the whole, the business layout of enterprises in the industry is relatively scattered, and the industry is in a state of disorderly competition.

At present, the enterprises engaged in surface treatment of auto parts mainly include Ireson surface technology (Suzhou) Co., Ltd., Jiangsu Fengdong Thermal Technology Co., Ltd., Yancheng Keao Machinery Co., Ltd., Anhui Qiming Surface Technology Co., Ltd. The scale of industry enterprises is generally small, and there are few large enterprises and listed enterprises. A representative industry leader has not been formed yet.

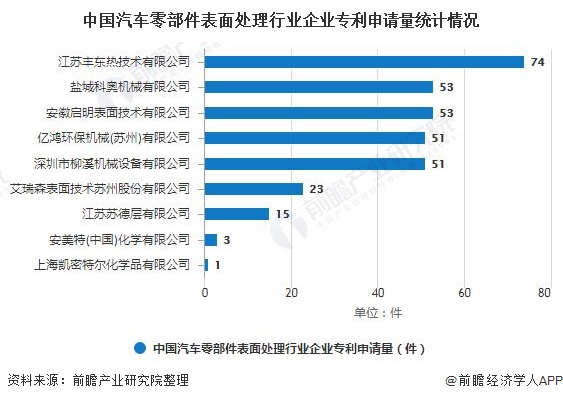

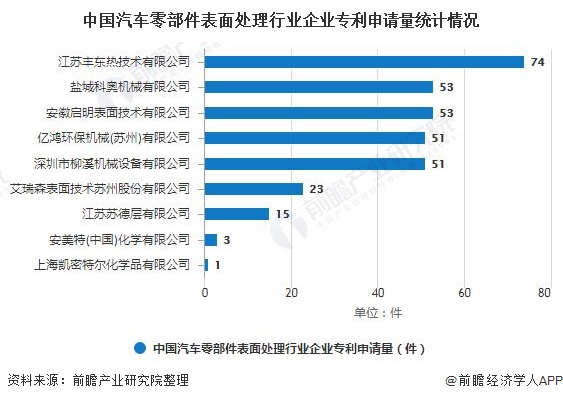

From the perspective of the number of patent applications of enterprises in the automobile parts surface treatment industry, the number of patent applications of enterprises is generally small. Jiangsu Fengdong Thermal Technology Co., Ltd. has the largest number of patent applications, with 74, followed by Yancheng Keao Machinery Co., Ltd. and Anhui Qiming Surface Technology Co., Ltd., with 53 patent applications.

3. Promote new technologies and processes to promote enterprise transformation and upgrading

"Industry 4.0" dominated by intelligent manufacturing is currently the transformation direction of Chinas manufacturing industry. At present, the overall automation level of Chinas automobile manufacturing industry is high, but there is a disconnect between the technology of automobile parts surface treatment enterprises and the technology level of automobile whole vehicle manufacturing. The surface strengthening process of domestic auto parts is mainly traditional process, and the degree of automation is low.

With new technologies such as industrial robots and industrial Internet, new processes such as robot electrostatic spraying, laser surface treatment, ion implantation and molecular membrane are gradually promoted within the industry, and the overall technical level of the industry will enter a new level.

1. Cluster development of enterprises in Chinas auto parts surface treatment industry

At present, there are more than 1000 enterprises engaged in the surface treatment of auto parts in China. The enterprises are mainly distributed in the Bohai rim, Yangtze River Delta, Pearl River Delta and central Hubei, showing a certain cluster effect.

From the perspective of enterprise scale, the industry is mainly small and medium-sized enterprises. Among the enterprises engaged in the surface treatment of auto parts, most of them have a registered capital of less than 10 million yuan.

At present, the surface treatment technologies of domestic auto parts surface treatment enterprises are still dominated by traditional electroplating, electrophoresis, phosphating, passivation and blackening, carburizing and nitriding, and the application proportion of new surface treatment technologies such as high-energy beam surface strengthening, plasma spraying, surface nano strengthening and surface composite strengthening technologies is still low, The overall technical level of the industry still has great room for improvement.

2. The business layout of Chinas auto parts surface treatment enterprises is scattered, and the industry is in a state of disorderly competition

Due to the limitation of enterprise scale, most enterprises are only engaged in one of the subdivided fields of automobile parts surface treatment, some are only engaged in the production of parts surface treatment agent, some are engaged in the pretreatment business of automobile parts, and some are engaged in the production and sales of surface treatment equipment (anti-corrosion equipment, cleaning equipment, electroplating equipment, etc.). On the whole, the business layout of enterprises in the industry is relatively scattered, and the industry is in a state of disorderly competition.

At present, the enterprises engaged in surface treatment of auto parts mainly include Ireson surface technology (Suzhou) Co., Ltd., Jiangsu Fengdong Thermal Technology Co., Ltd., Yancheng Keao Machinery Co., Ltd., Anhui Qiming Surface Technology Co., Ltd. The scale of industry enterprises is generally small, and there are few large enterprises and listed enterprises. A representative industry leader has not been formed yet.

From the perspective of the number of patent applications of enterprises in the automobile parts surface treatment industry, the number of patent applications of enterprises is generally small. Jiangsu Fengdong Thermal Technology Co., Ltd. has the largest number of patent applications, with 74, followed by Yancheng Keao Machinery Co., Ltd. and Anhui Qiming Surface Technology Co., Ltd., with 53 patent applications.

3. Promote new technologies and processes to promote enterprise transformation and upgrading

"Industry 4.0" dominated by intelligent manufacturing is currently the transformation direction of Chinas manufacturing industry. At present, the overall automation level of Chinas automobile manufacturing industry is high, but there is a disconnect between the technology of automobile parts surface treatment enterprises and the technology level of automobile whole vehicle manufacturing. The surface strengthening process of domestic auto parts is mainly traditional process, and the degree of automation is low.

With new technologies such as industrial robots and industrial Internet, new processes such as robot electrostatic spraying, laser surface treatment, ion implantation and molecular membrane are gradually promoted within the industry, and the overall technical level of the industry will enter a new level.