Fan Cheng [evert] innovative empowerment | the third generation of evert er7 robot is launched i

Опубликован в:2020-08-05

In summer, everything is towering.

On August 4, 2020, as a desktop robot focusing on 3C industry under "smart manufacturing expert, evert", the fully upgraded third-generation er7-700 robot shocked the market, and you are invited to taste and witness it together.

[01 "Ai" survey]

Evert broke into the desktop robot market because of a market research on 3C industry a few years ago. It was the market research of this trip to Guangdong that evert discovered the huge demand for desktop robots in 3C industry. Evert keenly felt that 3C industry is one of the most urgent industries for machine replacement, and it is also one of the bases for domestic robots to realize the "strategy of encircling the city from the countryside".

In the market research of 3C industry, evert found that in the application scenarios of high-precision loading and unloading, assembly, dispensing and detection, the dynamic response of general-purpose robot lags behind, which will affect the smooth operation of track after working for a long time, resulting in the increase of body noise and other phenomena. In the application scenario of multi station frequent switching, the general robot is easy to cause joint shaft damage and resonance caused by low-speed movement, which can not ensure the accuracy.

In the application scenarios of metal and plastic shell grinding, polishing, marking and gluing, the paint surface of the robot is often corroded by cutting fluid, which is easy to affect the long-term use of the robot. If the incoming consistency of the workpiece is unstable, the point position of the general robot is prone to offset after interference and collision, and the zero point needs to be recalibrated.

[02 "angstrom" iteration]

It is the market-oriented IPD product development process that helps evert upgrade the er7-700 robot for two consecutive generations according to the pain points and needs of subdivided industries, and quickly open up the situation in the strong 3C industry. The replacement of time sequence and the gilding of years are all generous gifts given by time. The evert er7-700 robot iterated to the third generation is more efficient, more accurate, easier to use, more stable, and more powerful in function and performance.

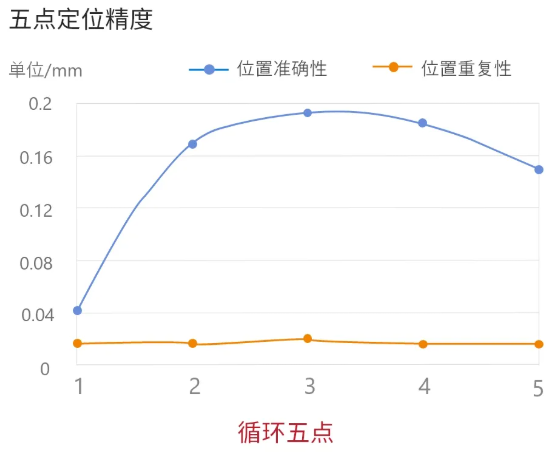

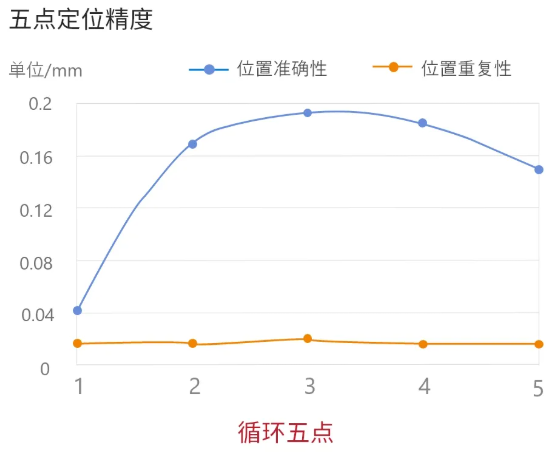

accurate

The new third-generation er7-700 robot has upgraded configuration, higher efficiency and 30% performance improvement. The repetitive positioning accuracy of er7-700 robot is ± 0.02mm. The dynamic feedforward function improves the trajectory accuracy by about 35%. It can be competent for deburring, grinding, gluing, gluing and other applications of non-metallic parts.

Er7-700 robot improves the acceleration of one axis for loading, unloading and handling occasions, with remarkable improvement effect. The comprehensive beat can be further improved by 20% - 30%.

High robustness

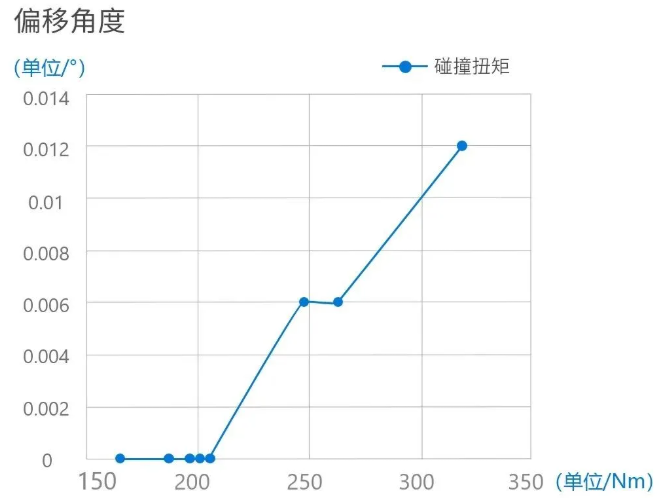

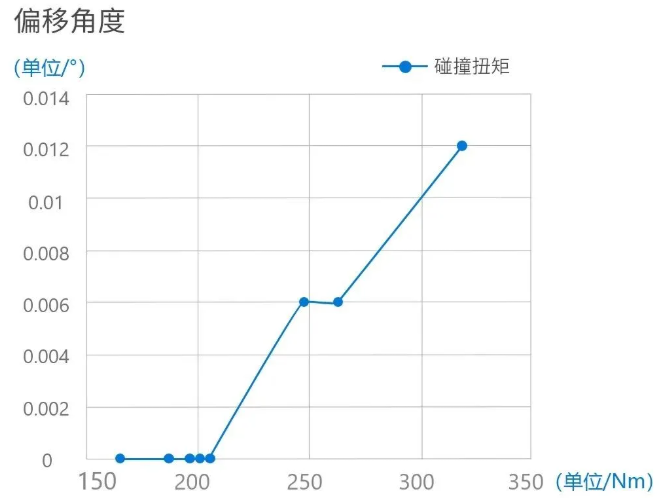

Er7-700 robot has high rigidity transmission design, which improves the anti deformation ability by 50%. Optimize the trajectory algorithm and arrive accurately. The connecting torque of er7-700 robot increases by 50%, and the actual collision torque reaches 210nm, which exceeds 33% of the allowable joint torque, which can effectively avoid the point offset after collision.

Easy to use

Er7-700 robot has friendly man-machine interface and is easy to operate. Reserved peripheral holes for easy installation. External signal line, easy to integrate. Compared with the general connector, the IO connector of er7-700 robot is reduced by half, which can effectively avoid interference with peripheral equipment. Er7-700 robot provides welded user terminal IO line, which can save users 2 hours of wire making time and 3 hours of wire welding time.

stable

Er7-700 robot has more sensitive dynamic detection and effectively reduces the occurrence of collision offset. The protection grade of er7-700 robot wrist reaches IP67 and the protection grade of its body reaches IP65. The surface is sprayed with emulsion resistant paint without wearing protective clothing. At the same time, it has peripheral pipeline fixing holes, which is convenient for users to fix peripheral pipelines.

The general body noise of er7-700 robot is 78dB, and the body noise of the new er7-700 robot is reduced to 68dB. The noise of general electric cabinet of er7-700 robot is 65dB, and that of new er7-700 robot is reduced to 55dB.

Behind every upgrade iteration of er7-700 robot, it is tempered and condensed countless wisdom and sweat. Behind every rain or shine, we go all out to help better experience and integration. Everts new generation of er7-700 robot breaks through the siege with hard core strength. We believe that with the brilliance of "heart", we will live up to our expectations!

On August 4, 2020, as a desktop robot focusing on 3C industry under "smart manufacturing expert, evert", the fully upgraded third-generation er7-700 robot shocked the market, and you are invited to taste and witness it together.

[01 "Ai" survey]

Evert broke into the desktop robot market because of a market research on 3C industry a few years ago. It was the market research of this trip to Guangdong that evert discovered the huge demand for desktop robots in 3C industry. Evert keenly felt that 3C industry is one of the most urgent industries for machine replacement, and it is also one of the bases for domestic robots to realize the "strategy of encircling the city from the countryside".

In the market research of 3C industry, evert found that in the application scenarios of high-precision loading and unloading, assembly, dispensing and detection, the dynamic response of general-purpose robot lags behind, which will affect the smooth operation of track after working for a long time, resulting in the increase of body noise and other phenomena. In the application scenario of multi station frequent switching, the general robot is easy to cause joint shaft damage and resonance caused by low-speed movement, which can not ensure the accuracy.

In the application scenarios of metal and plastic shell grinding, polishing, marking and gluing, the paint surface of the robot is often corroded by cutting fluid, which is easy to affect the long-term use of the robot. If the incoming consistency of the workpiece is unstable, the point position of the general robot is prone to offset after interference and collision, and the zero point needs to be recalibrated.

[02 "angstrom" iteration]

It is the market-oriented IPD product development process that helps evert upgrade the er7-700 robot for two consecutive generations according to the pain points and needs of subdivided industries, and quickly open up the situation in the strong 3C industry. The replacement of time sequence and the gilding of years are all generous gifts given by time. The evert er7-700 robot iterated to the third generation is more efficient, more accurate, easier to use, more stable, and more powerful in function and performance.

accurate

The new third-generation er7-700 robot has upgraded configuration, higher efficiency and 30% performance improvement. The repetitive positioning accuracy of er7-700 robot is ± 0.02mm. The dynamic feedforward function improves the trajectory accuracy by about 35%. It can be competent for deburring, grinding, gluing, gluing and other applications of non-metallic parts.

Er7-700 robot improves the acceleration of one axis for loading, unloading and handling occasions, with remarkable improvement effect. The comprehensive beat can be further improved by 20% - 30%.

High robustness

Er7-700 robot has high rigidity transmission design, which improves the anti deformation ability by 50%. Optimize the trajectory algorithm and arrive accurately. The connecting torque of er7-700 robot increases by 50%, and the actual collision torque reaches 210nm, which exceeds 33% of the allowable joint torque, which can effectively avoid the point offset after collision.

Easy to use

Er7-700 robot has friendly man-machine interface and is easy to operate. Reserved peripheral holes for easy installation. External signal line, easy to integrate. Compared with the general connector, the IO connector of er7-700 robot is reduced by half, which can effectively avoid interference with peripheral equipment. Er7-700 robot provides welded user terminal IO line, which can save users 2 hours of wire making time and 3 hours of wire welding time.

stable

Er7-700 robot has more sensitive dynamic detection and effectively reduces the occurrence of collision offset. The protection grade of er7-700 robot wrist reaches IP67 and the protection grade of its body reaches IP65. The surface is sprayed with emulsion resistant paint without wearing protective clothing. At the same time, it has peripheral pipeline fixing holes, which is convenient for users to fix peripheral pipelines.

The general body noise of er7-700 robot is 78dB, and the body noise of the new er7-700 robot is reduced to 68dB. The noise of general electric cabinet of er7-700 robot is 65dB, and that of new er7-700 robot is reduced to 55dB.

Behind every upgrade iteration of er7-700 robot, it is tempered and condensed countless wisdom and sweat. Behind every rain or shine, we go all out to help better experience and integration. Everts new generation of er7-700 robot breaks through the siege with hard core strength. We believe that with the brilliance of "heart", we will live up to our expectations!