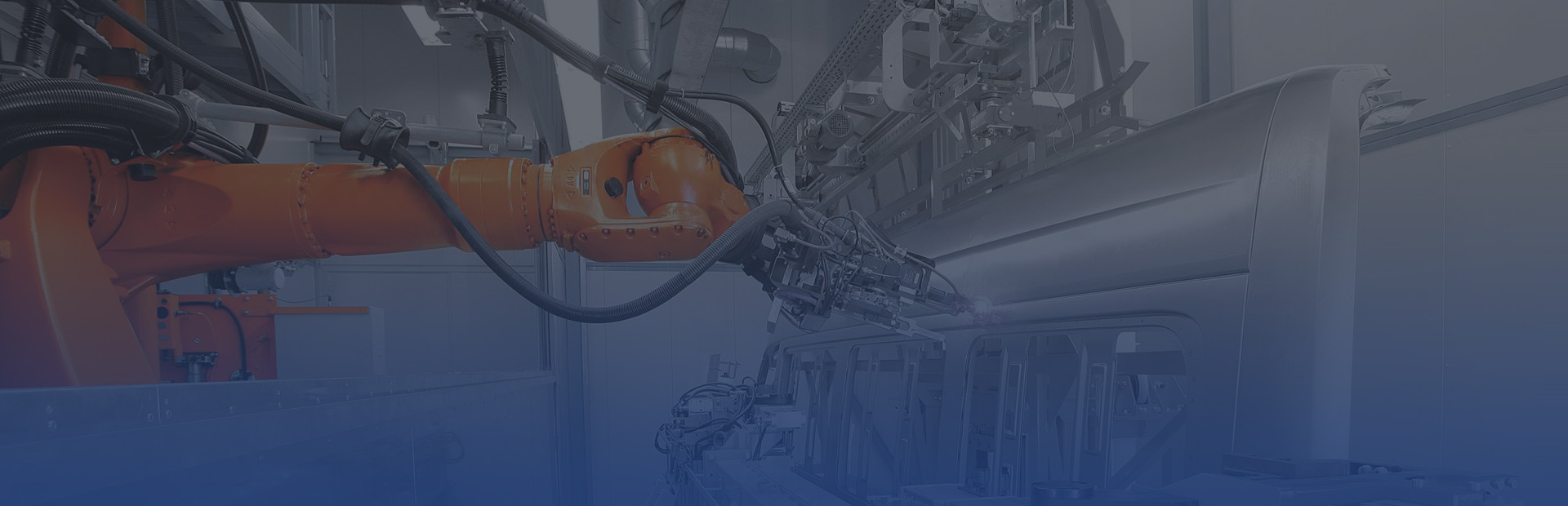

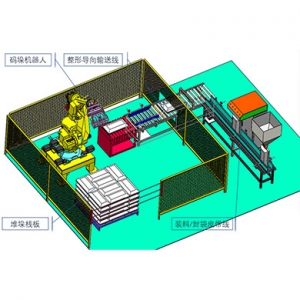

Robot engraving workstation

Consult Immediately

Национальная горячая линия: +86 0769-85832096

Подробности

The engraving robot uses robot related technologies such as multi axis linkage control, trajectory interpolation and off-line programming, and adopts PCNC hardware structure and control software. It can be applied to molds (such as tire molds), graphic engraving, advertising signs and arts and crafts production. As a product that can realize full automation of engraving, it has better performance in engraving speed, accuracy and fineness. It can easily and quickly carve realistic, exquisite and durable two-dimensional graphics and three-dimensional relief on various materials.

Product features:

7. Manual engraving often pays attention to detail engraving. Machine engraving cannot complete the engraving of details. Many details are not in place manually, so it is not suitable for ultra-fine engraving;

8. There is no labor cost for machine engraving, and the cost of manual engraving is very high, especially for master engraving, the price is much higher than that of machine engraving;

9. The carving robot has a larger workspace and can carve more complex handicrafts;

10. The engraving robot adopts different processing technologies according to different materials, which can easily and flexibly change to meet the needs;

11. The computer engraving system of engraving robot integrates the functions of scanning, editing, typesetting and engraving. It is a typical product of CAD / CAM integration. It can easily and quickly carve realistic, exquisite and durable two-dimensional graphics and three-dimensional relief on various materials.

Main configuration and performance:

20. Robot: Yaskawa, FANUC, KUKA, abb, six axis, 5kg-600kg

21. Engraving spindle: customized according to the required engraving materials and shape, 1000-30000 revolutions, equipped with various cutting tools;

22. Engraving software: sprutcam, etc

23. Positioner: linkage / non linkage, single axis / double axis / three axis;

24. Applicable materials: stone, wood, foam, etc.

25. Engravable modeling: 3D digital modeling. According to the samples, drawings, photos, manuscripts and other materials provided by customers, use 3D scanners or 3D modeling software (ZBrush, freefoem, carving pen, rhinoceros, 3dsmax, Maya, etc.) to create 3D digital models.

Product features:

7. Manual engraving often pays attention to detail engraving. Machine engraving cannot complete the engraving of details. Many details are not in place manually, so it is not suitable for ultra-fine engraving;

8. There is no labor cost for machine engraving, and the cost of manual engraving is very high, especially for master engraving, the price is much higher than that of machine engraving;

9. The carving robot has a larger workspace and can carve more complex handicrafts;

10. The engraving robot adopts different processing technologies according to different materials, which can easily and flexibly change to meet the needs;

11. The computer engraving system of engraving robot integrates the functions of scanning, editing, typesetting and engraving. It is a typical product of CAD / CAM integration. It can easily and quickly carve realistic, exquisite and durable two-dimensional graphics and three-dimensional relief on various materials.

Main configuration and performance:

20. Robot: Yaskawa, FANUC, KUKA, abb, six axis, 5kg-600kg

21. Engraving spindle: customized according to the required engraving materials and shape, 1000-30000 revolutions, equipped with various cutting tools;

22. Engraving software: sprutcam, etc

23. Positioner: linkage / non linkage, single axis / double axis / three axis;

24. Applicable materials: stone, wood, foam, etc.

25. Engravable modeling: 3D digital modeling. According to the samples, drawings, photos, manuscripts and other materials provided by customers, use 3D scanners or 3D modeling software (ZBrush, freefoem, carving pen, rhinoceros, 3dsmax, Maya, etc.) to create 3D digital models.

Предыдущий:Robot tapping machine

Следующий:Robot handling / picking / loading and unloading workstation