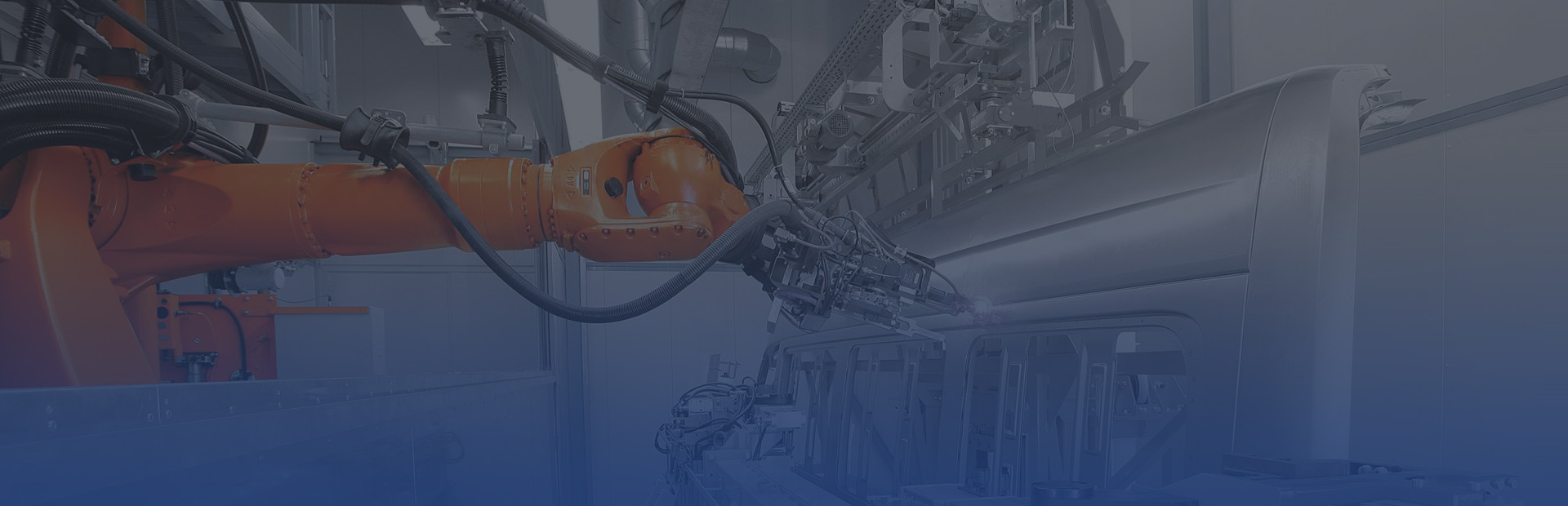

Robot handling / picking / loading and unloading workstation

Consult Immediately

Национальная горячая линия: +86 0769-85832096

Подробности

Handling robot is an industrial robot that can carry out automatic handling operation. Handling operation refers to holding the workpiece with a kind of equipment and moving it from one processing position to another. The handling robot can install different end effectors to complete the handling of workpieces with different shapes and states, which greatly reduces the heavy physical labor of human beings. More than 100000 handling robots are used in the world, which are widely used in machine tool loading and unloading, automatic production line of stamping machine, automatic assembly line, palletizing handling, automatic handling of containers, etc. Some developed countries have formulated the maximum limit of manual handling, and those exceeding the limit must be completed by the handling robot.

Product features:

1. It can complete various expected tasks through programming, and has the respective advantages of human and machine in its own structure and performance, especially reflecting artificial intelligence and adaptability;

2. It can operate for a long time, reduce the labor intensity, and work in a harmful environment;

3. It reduces the dependence on workers and can more effectively evaluate and adjust production capacity;

4. The equipment has high flexibility, multi-purpose production, reduces the cost of production equipment, shortens the preparation cycle of product transformation and replacement, and reduces the corresponding equipment investment.

Main configuration and performance:

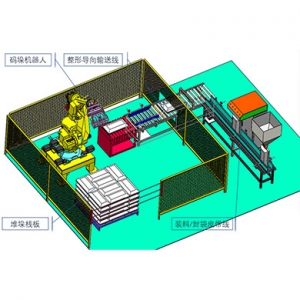

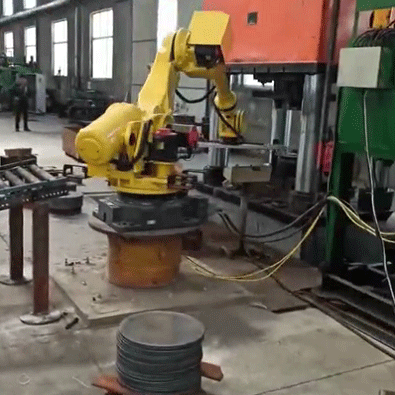

26. Robot: Yaskawa, FANUC, KUKA, abb, etc., four axis and six axis;

27. Load range: 5kg ~ 600kg;

28. Main applications: material handling, loading and unloading of machine tools, stamping automatic production line, etc;

29. Control mode: PLC + welding robot control system.

?

Product features:

1. It can complete various expected tasks through programming, and has the respective advantages of human and machine in its own structure and performance, especially reflecting artificial intelligence and adaptability;

2. It can operate for a long time, reduce the labor intensity, and work in a harmful environment;

3. It reduces the dependence on workers and can more effectively evaluate and adjust production capacity;

4. The equipment has high flexibility, multi-purpose production, reduces the cost of production equipment, shortens the preparation cycle of product transformation and replacement, and reduces the corresponding equipment investment.

Main configuration and performance:

26. Robot: Yaskawa, FANUC, KUKA, abb, etc., four axis and six axis;

27. Load range: 5kg ~ 600kg;

28. Main applications: material handling, loading and unloading of machine tools, stamping automatic production line, etc;

29. Control mode: PLC + welding robot control system.

?

Предыдущий:Robot engraving workstation

Следующий:Automatic palletizing production line